Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric ME96SSEA-MB

- Page 1 Electronic Multi-Measuring Instrument MODEL ME96SSEA-MB User's Manual: Detailed Edition Before operating the instrument, you should first read thoroughly ● this operation manual for safe operation and optimized performance of the product. Deliver this user's manual to the end user.

-

Page 2: Check On Your Delivery

Check on your delivery Check the following point as soon as you receive Mitsubishi Electronic Multi-Measuring Instrument Parts name Quantity Specifications User’s Manual A3 size (Simplified) Attachment lug (with screw) About the optional plug-in module sold separately This product cannot be installed the optional plug-in module. Please use a combination of other classes (ME96SSHA-MB, ME96SSRA-MB) and the optional plug-in module, if analog output, CC-Link communication, contact input and output, MODBUS®TCP communication or Logging function etc is required. -

Page 3: Features

Features This instrument measures the load status by inputting the secondary side of the VT and CT, and displays various measurement values. ⚫ This instrument supports active energy: class 0.5S. ⚫ The password protection setting avoids undesired change of settings or deletion of measured data. ⚫... -

Page 4: Table Of Contents

Table of Contents Check on your delivery ............................1 About the optional plug-in module sold separately ....................1 Features ................................... 2 Table of Contents ..............................3 Safety Precaution ..............................5 EMC Directive Instruction ............................9 Precautions for KC mark............................9 Instructions for Handling 1. - Page 5 Table of Contents 6. Other ................................. 47 6.1. Display Pattern Contents ........................47 6.2. Maximum Scale Value..........................49 6.3. Possible Setting Range for Maximum Scale ..................50 6.4. Measurement Items ..........................53 6.5. Measurement Characteristic ........................54 6.6. Troubleshooting ............................55 Installation Installation 1.

-

Page 6: Safety Precaution

Safety Precaution (Always read these instructions before using this equipment) For personnel and product safety please read the contents of these operating instructions carefully before using. Make sure that the end users read this manual and then keep the manual in a safe place for future reference. Make sure to deliver this manual to the end-user. - Page 7 Safety Precaution ■Others MODBUS ® T/R+,T/R-,SG,Ter terminals maxDC35V communication ⚫ Do not drop this instrument from high place. If you drop it and the display is cracked, do not touch the liquid crystal or get it in your mouth. If the liquid crystal is touched, wash it away at once.

- Page 8 Safety Precaution ■ Operation instructions ⚫ Before operating the product, check that active bare wire and so on does not exist around the product. If any bare wire exists, stop the operation immediately, and take an appropriate action such as isolation protection.

- Page 9 Safety Precaution ■ Guarantee ⚫ Gratis warranty is effective until the earlier of 1 year after the date of your purchase or 18 months after manufacturing. ⚫ The gratis warranty shall apply if the product fails even though it is being used properly in the conditions, with the methods and under the environments in accordance with the terms and precautions described in the catalogs, the instruction manual, caution label on the product, etc.

-

Page 10: Emc Directive Instruction

(Class A). Do not use the product in a residential area. ■ Applicant for KC mark : MITSUBISHI ELECTRIC AUTOMATION KOREA CO.,LTD ■ Manufacturer : MITSUBISHI ELECTRIC CORPORATION Note 1: This is the notification for the KC mark (Korea Certification) -

Page 11: Display And Button Functions Of Each Parts

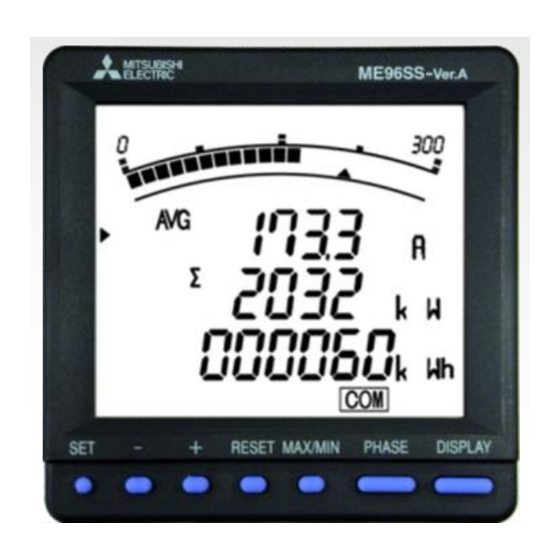

1. Display and Button Functions of Each Parts Part names ■Front view LCD with backlight Operation buttons (For details, refer to page 12.) ■Rear view (main unit) ® MODBUS RTU communication terminal ® T/R+: MODBUS RTU communication transmission terminal ® T/R-: MODBUS RTU communication transmission terminal SG: Signal Ground. - Page 12 1. Display and Button Functions of Each Parts Display Note: The above display is an example for explanation. Segment Name Description LEAD status They show direction of Power Factor on bar graph. LAG status Scale of the bar graph They show the scales of the bar graph. Under scale input Turns on when measuring values fall below the minimum scale.

- Page 13 1. Display and Button Functions of Each Parts Functions of operation buttons The operation buttons have various functions RESET MAX/MIN PHASE DISPLAY - + According to how they are pressed down. Set button Reset button Phase button Maximum/Minimum button Display button +/-button ○...

-

Page 14: Function Modes

2. Function Modes The following function modes are available for this Multi-Measuring instrument. Operation mode is displayed after auxiliary power turns on. It is then possible to switch to the desired mode. Reference Mode Description Pages P.38 to P.46 This mode is for displaying each measured value using digital numerical values and Operation bar graphs. -

Page 15: Setting

3. Setting 3.1. Setting flow To measure, it is necessary to use Setting mode to set the phase wire system, VT / direct voltage, and CT primary current. From Operation mode, move to Setting mode and then set necessary items. Factory default settings will be used for items that you do not set. - Page 16 3. Setting 3.1 Setting flow <Setting Procedure> ① ⑤After completion of setting, select ‘End’ in the setting Press simultaneously for 2 seconds to get in the setting mode. menu and press ② ⑥When the End display appears, press Select a setting menu number by once again.

-

Page 17: Setting Menu 1: Basic Settings (Setting The Phase Wire System, Display Pattern, Vt/Direct Voltage, Ct Primary Current, Etc.)

3. Setting 3.1 Setting flow Basic Operations for setting Function Operation Remarks Select a set value Press Fast-forward when pressed over 1 sec. Setting item will be cared and shift to the Setting items are saved Press next item. Go back to the previous setting item Press The set value for the setting item just before DISPLAY... - Page 18 3. Setting 3.2 Setting menu 1: Basic Settings (Setting the Phase Wire System, Display Pattern, VT/Direct Voltage, CT Primary Current, etc.) (2)For other phase wire system except 3-phase 4-wire Additional (2)For other phase wire system except 3-phase 4-wire display Additional display ○...

- Page 19 3. Setting 3.2 Setting menu 1: Basic Settings (Setting the Phase Wire System, Display Pattern, VT/Direct Voltage, CT Primary Current, etc.) Continued form the previous page (2) When using VT < > Set the secondary and primary voltages of the VT. (a)...

- Page 20 3. Setting 3.2 Setting menu 1: Basic Settings (Setting the Phase Wire System, Display Pattern, VT/Direct Voltage, CT Primary Current, etc.) Set the frequency. 50Hz 60Hz ⑤Frequency Note1.The scale value of the frequency of the bar graph display is changed, too. Set the time constant for current demand.

-

Page 21: Setting Menu 2: Communication Settings (Setting The Modbus ® Rtu Communication)

3. Setting 3.3. Setting Menu 2: Communication Settings (Setting the MODBUS ® RTU communication) In the operation mode, press simultaneously for 2 seconds or more, and the following operation becomes available. DISPLAY ® Set the MODBUS address number. Selectable addresses: 1 to 255 ®... -

Page 22: Setting Menu 3: Display Settings (Setting Maximum Scale And Harmonic Display)

3. Setting 3.4. Setting Menu 3: Display Settings (Setting Maximum Scale and Harmonic Display) This section shows how to set maximum scale in the bar graph and harmonics display. In the operation mode, press simultaneously for 2 seconds or more, and the following operation becomes available. - Page 23 3. Setting 3.4 Setting Menu 3: Display Settings (Setting Maximum Scale and Harmonic Display) Set the power factor scale. If you have not set power factor to “Display pattern”, this display will be skipped. ④Power factor scale -0.5 to 1 to 0.5 -0 to 1 to 0 DISPLAY According to the setting flow (page 14), save the changed...

-

Page 24: Setting Menu 4: Lcd Settings (Setting Model Display, Version Display, Backlight, And Display Update Time)

The model can be confirmed. (This is only display, and settings cannot be changed.) (1) Middle Line Model ① Model Display ME96SSEA-MB The product version can be checked. (The product version is displayed, but cannot be changed.) ②Version display The backlight brightness can be adjusted. ③... -

Page 25: Setting Menu 5: Alarm Settings (Setting Upper/Lower Limit Alarm, Motor Starting Current Mask Function, Etc.)

3. Setting Alarm Settings (Setting Upper/Lower Limit Alarm, Motor Starting 3.6. Setting Menu 5: Current Mask Function, etc.) This section shows how to set the upper/lower limit alarm, backlight flickering during alarm and, motor starting current delay time. In the operation mode, press simultaneously for 2 seconds or more, and the following operation becomes available. - Page 26 3. Setting 3.6 Setting Menu 5: Alarm Settings (Setting Upper/Lower Limit Alarm, Motor Starting Current Mask Function, etc.) Set the alarm value for upper/lower limit alarm element 1. The following table shows the setting range. Setting Measuring element Setting range step(Note) 5 to 100 to 120(%) A, AN, DA, DAN upper limit...

- Page 27 3. Setting 3.6 Setting Menu 5: Alarm Settings (Setting Upper/Lower Limit Alarm, Motor Starting Current Mask Function , etc.) It is possible to make the backlight to flicker when an alarm is generated. ⑦ Backlight flickers (Not flicker) (Flicker) during alarms Note: When all settings for ①Alarm item 1 and ③Alarm item 2 to 4 are set to "non,"...

-

Page 28: Setting Menu 6: No Settings

3. Setting 3.7. Setting Menu 6: No Settings Since there is no corresponding function, this setting item is not displayed. No Settings 3.8. Setting Menu 7: Since there is no corresponding function, this setting item is not displayed. -

Page 29: Setting Menu 8:Special Settings (Setting Operation Time, Phase Display, Iec Mode)

3. Setting 8:Special Settings (Setting Operation Time, Phase Display, IEC Mode) 3.9. Setting Menu Set the operation time, phase display, IEC mode. In the operation mode, press simultaneously for 2 seconds or more, and the following operation becomes available. For more details about each function, refer to the corresponding pages. - Page 30 3. Setting 3.10. Setting Menu 8: Special Settings (Setting Operation Time, Phase Display, IEC Mode) Set the phase display. ④Phase display setting DISPLAY By the setting of this mode, the following calculation methods and signs are changed. ・Each measurement item display during power transmission. (Refer to page 42) ・Appendix : Calculation methods of ME96SS (Refer to page 68) ⑤Set IEC mode...

-

Page 31: Setting Value Confirmation Menus 1-9: Confirming The Settings In The Setting Menus

3. Setting 3.10. Setting Value Confirmation Menus 1-9: Confirming the Settings in the Setting Menus 1-8 and Test Mode in Setting Menu 9 ⚫ Setting Value Confirmation When is pressed for at least 2 seconds in the operation mode, the following operation becomes available. The screen transitions and operations are the same as for Setting Menus 1 to 8 and CL. -

Page 32: Initializing Related Items By Changing Settings

3. Setting 3.11. Initializing Related Items by Changing Settings When a setting value is changed, the related setting items and measurement data (maximum/minimum values) will return to the default settings. Refer to the following list. Menu 1 Menu 5 Menu 8 Setting item to be changed CT current Initialized item... -

Page 33: Setting The Special Display Pattern P00

3. Setting 3.13. Setting the Special Display Pattern P00 Even if there is no display pattern that you like in the display patterns P01 to P13, individual setting is available by the display pattern P00. This setting is made in the setting menu 1. Explanation begins with the set “P00” in ②display pattern of the setting menu 1 (page 16). - Page 34 3. Setting 3.13.Setting the Special Display Pattern P00 Continued form the previous page (5) Set the display of the display 4-2. Select “yES” by and press When you do not want to display the display 2, select “no” and press (6)...

-

Page 35: Examples Of Simple Settings

3. Setting 3.14. Examples of Simple Settings The following shows a simple setting example. ME96SSEA-MB ■Setting Example Model: Phase wire system : 3-phase 4-wire A, V, W, PF Measuring element : Input Voltage :220/380V CT primary current : 200A CT Secondary current:5A... - Page 36 3. Setting 3.14. Examples of Simple Settings ® MODBUS The factory default setting is "EVEn(even)," so just press SET. parity Setting menu Set the setting menu number to "End" and then press SET.

-

Page 37: Using Test Mode

4. Using Test Mode Test mode includes functions that can be used for start-up of equipment. The following table shows what can be done in the test mode. Test menu Description For MODBUS®RTU communication function, it is possible to monitor fixed numerical Communication test data without measurement (voltage/current) input. -

Page 38: Test Menu 1: Communication Test

4. Using Test Mode 4.1. Test Menu 1: Communication Test In the setting value confirmation mode, when the menu number is set to "9", you will enter the test mode. Set the test menu number to "1". (as shown in the right figure) Test menu Execute communication test operation. -

Page 39: Operation

5. Operation 5.1. Basic Operation Display items and the order differ depending on the phase wire The following explains basic usages during operation. method setting display pattern settings and additional screen. ⚫ Switch display For more information about detailed display patterns, refer to pages 47 and 48. -

Page 40: Bar Graph Display

5. Operation 5.1. Basic Operation ⚫ Bar graph display Bar graph displays the measurement element indicated with “ ” or “ ”. (Example) Lower element (V) (Example) PF displayed on displayed on bar graph bar graph ⚫ Switching measurement factors displayed on bar graphs Press the button to switch. -

Page 41: Cyclic Display

5. Operation 5.1. Basic Operation ⚫ Cyclic Display In cyclic display, display and phases automatically change at every 5 seconds. When is pressed for about 2 seconds, the cyclic display appears. DISPLAY When is pressed for about 2 seconds, the cyclic phase appears. By pressing any other buttons except , cyclic display mode ends. -

Page 42: Maximum Value And Minimum Value Display

5. Operation 5.1. Basic Operation ⚫ Maximum value and minimum value display For the maximum / minimum value display screen, the maximum value, current value, and minimum value for each measurement item are displayed on one screen. However, for harmonics only the following maximum values are displayed. Harmonic current: Total effective values for where the phase was largest for each phase. -

Page 43: Active Energy Display

5. Operation 5.1. Basic Operation ⚫ Active Energy Display ■ Display format The following table shows the display format of active energy based on the total load. α: 1 1-phase 2-wire α x (VT primary voltage) x (CT primary current) √... -

Page 44: Demand Time And Demand Value Of Current Demand

5. Operation 5.1. Basic Operation ⚫ Demand time and demand value of current demand The demand time (t ) is the time until the measurement display value (I ) displays 95% of the input (I) when a certain constant input (I) is given. To display 100% of the input (I), about three times more than the time (t ) is needed. -

Page 45: Usage According To Purpose (Alarm, Operating Time, Password, Etc.)

5. Operation 5.2. Usage According to Purpose (Alarm, Operating Time, Password, etc.) The following explains usage according to the purpose during operation. ⚫ Display and operation of the upper/lower limit alarm When the value exceeds the upper or lower limit setting value set in advance, the display flickers. (For more information about how to set the upper/lower limit alarm, refer to page 24 and after.) -

Page 46: Canceling The Upper/Lower Limit Alarm

5. Operation 5.2 Usage According to Purpose (Alarm, Operating Time, Password, etc.) ⚫ Canceling the upper/lower limit alarm The upper and lower limit alarms can be The alarm cancellation method differs depending on the setting for alarm reset. cancelled also via communication. Alarm cancel method Cancelation method When the measurement value is below the upper/lower limit set value, the alarm is... -

Page 47: Preventing Maximum Value Update By Motor Starting Current

5. Operation 5.2 Usage According to Purpose (Alarm, Operating Time, Password, etc.) ⚫ Preventing maximum value update by motor starting current When the motor current is monitored, use the motor starting current delay function to prevent maximum value update and alarm generation for the current, active power, reactive power, apparent Power ,and power factor due to the motor starting current. -

Page 48: Other

6. Other 6.1. Display Pattern Contents When the display pattern in the Setting menu 1 and the additional screen in the Setting menus 3 and 8 are set, pressing changes the screens shown in the table below from the left to the right. [For 3-phase 4-wire] Screen set by display pattern Additional display (Set in the setting menus 3, 8) - Page 49 6. Other 6.1 Display Pattern Contents [For others except 3-phase 4-wire] Screen set by display pattern Additional display (Set in the setting menus 3, 8) Display No.7 No.6 No.8 No.9 No.10 pattern No.1 No.2 No.3 No.4 No.5 Harmonic Harmonic Operation Operation current voltage...

-

Page 50: Maximum Scale Value

6. Other 6.2. Maximum Scale Value Settable primary voltage, primary current, and standard maximum scale value are shown in the tables below. ● ● Maximum scale value of each item Specific power value for scale calculation Phase line Specific power Measurement element Maximum scale value Rated voltage... -

Page 51: Possible Setting Range For Maximum Scale

6. Other 6.3. Possible Setting Range for Maximum Scale The maximum scale of current can be selected from about 40% to 120% of rating, and maximum scale of voltage can be selected from about 20% to 250% of rating, and maximum scale of active power and reactive power can be selected from about 20% to 120% of rating. - Page 52 6. Other 6.3 Possible Setting Range for Maximum Scale ■Voltage maximum scale value Possible setting range:-18 STEP to +10STEP of the standard maximum scale value. Example: When the standard maximum scale value is 100V, the value is from 20V to 320V. Voltage maximum scale value (1/3) Voltage maximum scale value (2/3) Voltage maximum scale value (3/3)

- Page 53 6. Other 6.3 Possible Setting Range for Maximum Scale ■Maximum scale value for active power Possible setting range:-18 STEP to +3STEP of the rating Example: When the rating is 1000W, the value is from 200W to 1600W. Maximum scale value Maximum scale value Maximum scale value Maximum scale value...

-

Page 54: Measurement Items

6. Other 6.4. Measurement Items The table below shows the measurement items. ○:Data can be measured and displayed -:Data cannot be measured and displayed Item measurement display 3-phase 3-wire(2CT) Commu Measurement item 3-phase 4-wire 3-phase 3-wire(3CT) 1-phase 2-wire 1-phase 3-wire nication Inst Inst... -

Page 55: Measurement Characteristic

6. Other 6.5. Measurement Characteristic ■Metering actions in other than operation mode Status Measurement Display Several seconds No measurement No display just after turning on the auxiliary power supply (Backlight is lit, and LCD is not lit.) Setting mode, Same actions as in No display of Set value operation mode... -

Page 56: Troubleshooting

6. Other 6.6. Troubleshooting In the case of abnormal noise, odor, smoke, or heat generation from this instrument, turn it off at once. Check the followings before you ask for repair. Condition Possible cause Solution Auxiliary power supply is not impressed on The display is not lit. -

Page 57: Installation 1. Dimensions

Installation 1. Dimensions ME96SSEA-MB... -

Page 58: Installation 2. Mounting

Installation 2. Mounting 1 Dimensions of mounting holes The drilling dimensions of the panel are as shown in the right figure. The product can be installed to a panel having a thickness of 1.6 to 4.0 mm. 2 Mounting position The contrast of the LCD changes depending on the angle at which it is viewed. -

Page 59: Installation 3. Wiring

Installation 3. Wiring 1 Applicable electric wire specifications The following table shows applicable electric wire sizes Tightening Section Screw type Specification of wire used torques Terminal of main unit. ・Use crimping terminals: AWG26 to 14 (Connectable 2 wires) (Auxiliary power, Voltage input, Applicable crimping terminals: Current input,... - Page 60 Installation 3. Wiring Do not work with live wires Do not connect with live wires. It may cause electric shock, burns, device burn out, or fire. It is recommended that a protection fuse be used for VT and the auxiliary power source. Do not open the secondary side of the CT circuit Connect the CT secondary side signal correctly to the terminal for CT connection.

-

Page 61: Installation 4. Wiring Diagram

Installation 4. Wiring Diagram Rating voltage for every phase wire system Phase wire type Type Rating voltage Figure 3-phase 4-wire type STAR max AC277V(L-N)/480V(L-L) Figure 1 DELTA max AC220V(L-L) Figure 2 3-phase 3-wire type STAR max AC440V(L-L) Figure 3 1-phase 3-wire type ―... - Page 62 Installation 4. Wiring Diagram 3-phase 4-wire type: Direct input ①Auxiliary power supply AC100 to 240V or DC100 to 240V. ②Fuses 0.5A ③Some MODBUS®RTU equipment doesn’t have SG. In this case, the wiring between SG is unnecessary. Note 1: For low voltage circuits, grounding the secondary side of VT and CT is not t necessary. 3-phase 4-wire type: With VT ①Auxiliary power supply AC100 to 240V or DC100 to 240V.

- Page 63 Installation 4. Wiring Diagram 3-phase 3-wire(2CT) type: Direct input ①Auxiliary power supply AC100 to 240V or DC100 to 240V. ②Fuses 0.5A ③Some MODBUS®RTU equipment doesn’t have SG. In this case, the wiring between SG is unnecessary. Note 1: For low voltage circuits, grounding the secondary side of VT and CT is not t necessary. Note 2: Do not connect to NC terminal.

- Page 64 Installation 4. Wiring Diagram 1-phase 3-wire type ①Auxiliary power supply AC100 to 240V or DC100 to 240V. ②Fuses 0.5A ③Some MODBUS®RTU equipment doesn’t have SG. In this case, the wiring between SG is unnecessary. Note 1: For low voltage circuits, grounding the secondary side of CT is not t necessary. 1-phase 2-wire type: With VT ①Auxiliary power supply AC100 to 240V or DC100 to 240V.

- Page 65 Installation 4. Wiring Diagram Note for Input 1. The voltage input terminals for 3-phase 3-wire are different from those for others. 2. If the polarity for VT and CT are wrong, the measurement cannot be executed correctly. 3. Do not connect wires to the NC terminals. Note 4.

-

Page 66: Specifications

Specifications 1. Specification Type ME96SSEA-MB 3-PHASE 4-WIRE, 3-PHASE 3-WIRE(3CT, 2CT), 1-PHASE 3-WIRE, 1-PHASE 2-WIRE Phase wire system (common) AC5A, AC1A (common) Current 3-PHASE 4-WIRE:max AC277/480V 3-PHASE 3-WIRE:(DELTA)max AC220V, (STAR)max AC440V Rating Voltage 1-PHASE 3-WIRE:max AC220/440V 1-PHASE 2-WIRE:(DELTA)max AC220V, (STAR)max AC440V... -

Page 67: Applicable Standards

Specifications 2. Applicable Standards Electromagnetic Compatibility Emissions EN61326-1/CISPR 11, Radiated Emission FCC Part15 Subpart B Class A EN61326-1/CISPR 11 Conducted Emission FCC Part15 Subpart B Class A Harmonics Measurement EN61000-3-2 Flicker Meter Measurement EN61000-3-3 Immunity Electrostatic discharge Immunity EN61326-1/EN61000-4-2 Radio Frequency Electromagnetic field Immunity EN61326-1/EN61000-4-3 Electrical Fast Transient/Burst Immunity EN61326-1/EN61000-4-4... -

Page 68: Setting Table (Factory Settings And Customer Setting Note)

Specifications 4. Setting Table (Factory Settings and Customer Setting Note) Setting menu No. Setting items Initial content Memo Phase wire system 3P4(3-phase 4-wire) Display pattern ― 1.2.1 Pattern P00 VT/direct selection no(No VT) 1.3.1 Direct voltage 220/380V ― 1.3.2 VT secondary voltage ―... -

Page 69: Appendix

Appendix 1. Calculation methods of ME96SS (for 3 phase unbalanced system with neutral) Item Normal mode IEC mode Remark − R.m.s current for phase p R.m.s neutral current Lp-N r.m.s voltage − − Lp-Lg r.m.s voltage Active power for phase p Refer to page 42 for the sign. - Page 70 Vte. Agua Santa 4211 Casilla 30-D (P.O. Box) Vina del Mar, Chile +56-32-2-320-600 Mitsubishi Electric Automation (China) Ltd. Mitsubishi Electric Automation Building, No.1386 Hongqiao Road, Shanghai, China 200336 +86-21-2322-3030 Mitsubishi Electric Automation (China) Ltd. 5/F,ONE INDIGO,20 Jiuxianqiao Road Chaoyang District,Beijing, China 100016...