Summary of Contents for Toro 74419

- Page 1 Form No. 3356-852 Rev C TimeCutter® Z380 and Z420 Riding Mowers Model No. 74419—Serial No. 270000001 and Up Model No. 74420—Serial No. 270000001 and Up Register your product at www.Toro.com Original Instructions (EN)

-

Page 2: Table Of Contents

Whenever you need service, genuine Toro parts, Safety ..............4 or additional information, contact an Authorized Safe Operation Practices for Service Dealer or Toro Customer Service and have Ride-on (riding) the model and serial numbers of your product Rotary Lawnmower ready. - Page 3 Removing and Installing the Engine Hood..... 22 Lubrication..........23 Greasing the Bearings ......23 Engine Maintenance........23 Servicing the Air Cleaner ....23 Servicing the Engine Oil ....24 Servicing the Spark Plug ....26 Fuel System Maintenance ......27 Draining the Fuel Tank ......

-

Page 4: Safety

Safety ◊ being driven too fast; ◊ inadequate braking; Safe Operation Practices ◊ the type of machine is unsuitable for its for Ride-on (riding) Rotary task; Lawnmower Machines ◊ lack of awareness of the effect of ground conditions, especially slopes; This machine meets or exceeds European ◊... -

Page 5: Toro Riding Mower Safety

– stop the engine and remove the key. Toro Riding Mower Safety • Disengage drive to attachments, stop the engine, and disconnect the spark plug wire(s) The following list contains safety information or remove the ignition key specific to Toro products or other safety... -

Page 6: Sound Pressure

86 dBA, sparks, and flames away from battery. based on measurements of identical machines per • Use only genuine Toro replacement parts to EN 11094 and EN 836. ensure that original standards are maintained. - Page 7 This unit has an equivalent continuous A-weighted whole body vibration level of .195 m/s , based on measurements of identical machines per EN 1032. Model 74420 This unit has an equivalent continuous A-weighted hand/arm vibration level of 4.66 m/s , based on measurements of identical machines per EN 1033.

-

Page 8: Slope Chart

Slope Chart... -

Page 9: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 93-6677 1. Warning—don’t operate the mower with the deector up or removed;... - Page 10 106-2223 106-8742 1. Parking brake 106-2224 106-8743 1. Throttle 7. Headlights 2. Choke 8. Engine—stop 1. Height of cut 3. Fast 9. Engine—run 4. Continuous variable setting10. Engine—start 5. Slow 11. Ignition 6. Power take-off (PTO), Blade control switch on some models Battery Symbols Some or all of these symbols are on your battery...

- Page 11 110-6567 1. Warning—read the Operator’s Manual. 2. Warning—read the instructions before servicing or performing maintenance; move the motion control levers to the brake position, remove the ignition key and disconnect the spark plug wire. 3. Cutting/dismemberment hazard, mower blade; entanglement hazard, belt—do not open or remove safety shields while engine is running.

-

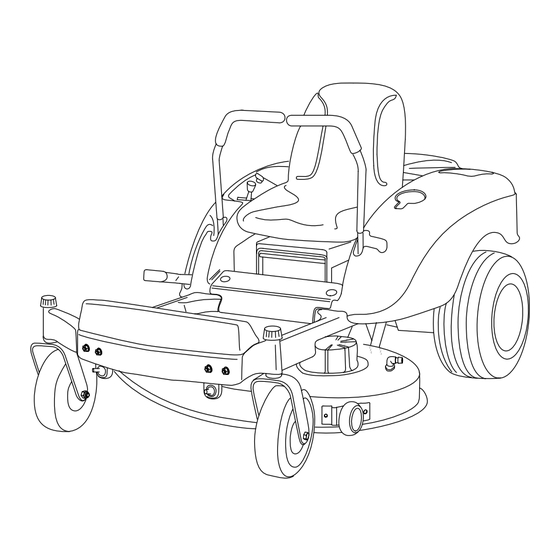

Page 12: Product Overview

Product Overview Figure 3 1. Seat 4. Height of cut lever 7. Front caster wheel 10. Anti-scalp roller 2. Control levers 5. Mower deck 8. Rear drive wheel 3. Control panel 6. Footrest 9. Cup holder... -

Page 13: Controls

Controls operator to exit the machine (Figure 4). Always position the motion control levers into the park Become familiar with all of the controls Figure 5 position when you stop the machine or leave it and Figure 4 before you start the engine and unattended. -

Page 14: Operation

Operation Recommended Gasoline Use UNLEADED Regular Gasoline suitable Note: Determine the left and right sides of the for automotive use (87 pump octane minimum). machine from the normal operating position. Leaded regular gasoline may be used if unleaded regular is not available. Think Safety First Important: Never use methanol, gasoline containing methanol, or gasohol containing... -

Page 15: Checking The Engine Oil Level

• Cleans the engine while it runs • Eliminates gum-like varnish buildup in the fuel In certain conditions during fueling, static system, which causes hard starting electricity can be released causing a spark Important: Do not use fuel additives which can ignite the gasoline vapors. A fire containing methanol or ethanol. -

Page 16: Operating The Blades

Figure 9 3. Start 1. Off 2. Run 4. Ignition Figure 7 Stopping the Engine 1. Blade control switch—On 2. Blade control switch—Off 1. Move the throttle lever to Fast (Figure 8). 3. Move the throttle lever to Choke before 2. -

Page 17: The Safety Interlock System

does not operate as described below, have an Authorized Service Dealer repair the safety system immediately. 1. While sitting on the seat, with the control levers in park position, and move the blade control switch to On. Try starting the engine; the engine should not crank. -

Page 18: Stopping The Machine

Stopping the Machine Forward 1. Move the levers to the center, unlocked To stop the machine, move the motion control position. levers to neutral and outward to the park position, disengage the blade control switch, ensure the 2. To go forward, slowly push the motion control throttle is in the fast position, and turn the ignition levers forward (Figure 11). -

Page 19: Positioning The Seat

Positioning the Seat The seat can move forward and backward. Position the seat where you have the best control of the machine and are most comfortable. 1. Raise the seat and loosen the adjustment knobs enough to move the seat (Figure 13). Important: Make sure that the spacers stay in place when loosening the knobs to move the seat. -

Page 20: Adjusting The Footrest

Side Discharge The mower has a hinged grass deflector that disperses clippings to the side and down toward the turf. Without the grass deflector, discharge cover, or complete grass catcher assembly mounted in place, you and others are exposed to blade contact and thrown debris. Contact with rotating mower blade(s) and thrown debris will cause injury or death. -

Page 21: Blade Maintenance

If a blade is Mow at Correct Intervals damaged or worn, replace it immediately with a genuine Toro replacement blade. Normally, mow every four days. But remember, grass grows at different rates at different times. -

Page 22: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval After the rst 8 operating • Change the engine oil. hours • Check the safety interlock system. •... -

Page 23: Lubrication

Figure 17 1. Engine hood 2. Knob Figure 19 2. To install the hood, put the hooks into the 1. Front caster tire slots and slide forward (Figure 18). 3. Tighten the knobs in the engine hood (Figure 17). Figure 20 4. -

Page 24: Servicing The Engine Oil

Cleaning the Foam Element and wait for all moving parts to stop before leaving the operating position. 1. Wash the foam element in liquid soap and 3. Clean around the air cleaner to prevent dirt warm water. When the element is clean, rinse from getting into the engine and causing it thoroughly. -

Page 25: Changing The Oil

Figure 25 1. Oil dipstick 2. Metal end Figure 23 4. Screw the oil dipstick fully onto the fill hole. Unscrew the dipstick, pull it out, and look at the end. If the oil level is low, slowly pour only enough oil into the fill hole to raise the level to, Checking the Oil Level but not over, the Full mark on the dipstick. -

Page 26: Servicing The Spark Plug

7. When oil has drained completely, close the tighten the filter an additional 1/2 to 3/4 turn drain valve. (Figure 27). 5. Fill the crankcase with the proper type of new 8. Remove the drain hose (Figure 26). oil; refer to Changing and Draining the Oil in Note: Dispose of the used oil at a recycling Engine Maintenance, page 23. -

Page 27: Fuel System Maintenance

Important: Never clean the spark plug. 2. Move the motion control levers outward to the Always replace the spark plug when it has park position, stop the engine, remove the key, a black coating, worn electrodes, an oily and wait for all moving parts to stop before film, or cracks. -

Page 28: Replacing The Fuel Filter

Note: Now is the best time to install a new Removing the Battery fuel filter because the fuel tank is empty. 7. Install the fuel line onto the fuel filter. Slide the hose clamp close to the fuel filter to secure Battery terminals or metal tools could short the fuel line (Figure 31). -

Page 29: Adding Water To The Battery

the Battery in Electrical System Maintenance, page 28. Adding Water to the Battery The best time to add distilled water to the battery is just before you operate the machine. This lets the water mix thoroughly with the electrolyte solution. 1. -

Page 30: Servicing The Fuses

disconnect the charger leads from the battery • Charge Circuit F2-25 amp, blade-type posts (Figure 34). • Optional Headlight Kit-10 amp, blade type 1. Raise the seat to gain access to the fuse holder (Figure 35). 2. To replace a fuse, pull out on the fuse to remove it (Figure 35). -

Page 31: Mower Maintenance

(Figure 38). Note this dimension. and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade. For convenient sharpening and replacement, you may want to keep extra blades on hand. -

Page 32: Leveling The Mower From

To ensure optimum performance and continued safety conformance of the machine, use genuine Toro replacement blades. Replacement blades made by other manufacturers may result in Figure 41 non-conformance with safety standards. -

Page 33: Adjusting The Front-To-Rear Blade Slope

3. Check the air pressure of all four tires. If needed, adjust to the recommended inflation; refer to Checking the Tire Pressure in Drive System Maintenance, page 30. 4. Set the height-of-cut lever to position D [3 inch (76 mm)]. 5. - Page 34 refer to Checking the Tire Pressure in Drive System Maintenance, page 30. 4. Check and adjust the side-to-side blade level if you have not checked the setting; refer to Leveling the Mower from Side-to-Side. 5. Measure the length of the rod extending out of the adjusting block on the sides of the chassis (Figure 45).

-

Page 35: Removing The Mower

level of the mower; refer to Leveling the Mower from Side-to-Side. Removing the Mower Note: Before removing the mower, make a note for which holes are used in the leveling brackets (Figure 49). 1. Park the machine on a level surface and disengage the blade control switch. -

Page 36: Installing The Mower

and wait for all moving parts to stop before leaving the operating position. 3. Slide the mower under the machine. 4. Lower the height-of-cut lever to the lowest position. 5. Attach the adjusting rod to the machine with the washer and hairpin cotter (Figure 49) on each side of the mower. -

Page 37: Cleaning

Slide rod through second grass deflector bracket and internal lock washer (Figure 51). 7. Insert rod at front of grass deflector into short stand-off on deck. Secure rear end of rod into the mower with a nut (3/8 inch) (Figure 51). Important: The grass deflector must be spring loaded in the down position. -

Page 38: Storage

Storage Stop the engine, allow it to cool, and drain the fuel tank; refer to Draining the Fuel Tank in Fuel System Maintenance, page 27. Cleaning and Storage Restart the engine and run it until it stops. 1. Disengage the blade control switch, move the Choke or prime the engine. -

Page 39: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The engine overheats. 1. The engine load is 1. Reduce ground speed. excessive. 2. The oil level in the 2. Add oil to the crankcase. crankcase is low. 3. The cooling ns and 3. Remove the obstruction air passages under the from the cooling ns and engine blower housing... - Page 40 Problem Possible Cause Corrective Action The engine will not start, 1. The fuel tank is empty. 1. Fill the fuel tank. starts hard, or fails to keep 2. The fuel valve turned off. 2. Open the fuel valve. running. 3. The choke is not on. 3.

- Page 41 Problem Possible Cause Corrective Action There is abnormal vibration. 1. The engine mounting 1. Tighten the engine bolts are loose. mounting bolts. 2. The engine pulley, idler 2. Tighten the appropriate pulley, or blade pulley is pulley. loose. 3. The engine pulley is 3.

-

Page 42: Schematics

Schematics Electrical Diagram (Rev. B) - Page 43 Spypros Stavrinides Limited Cyprus 357 22 434131 Surge Systems India Limited India 91 1 292299901 Hungary T-Markt Logistics Ltd 36 26 525 500 Toro Australia Australia 61 3 9580 7355 Toro Europe BVBA 32 14 562 960 Belgium 374-0102 Rev A...

- Page 44 Instructions for Obtaining Warranty Service The Toro® Company and its afliate, Toro Warranty Company, If you think that your Toro Product contains a defect in materials pursuant to an agreement between them, jointly promises to the or workmanship, follow this procedure: original purchaser* to repair any Toro Product used for normal 1.