Toro TimeCutter HD MyRide 75210 Operator's Manual

48in riding mower

Hide thumbs

Also See for TimeCutter HD MyRide 75210:

- Operator's manual (56 pages) ,

- Setup (4 pages) ,

- Setup instructions (4 pages)

Summary of Contents for Toro TimeCutter HD MyRide 75210

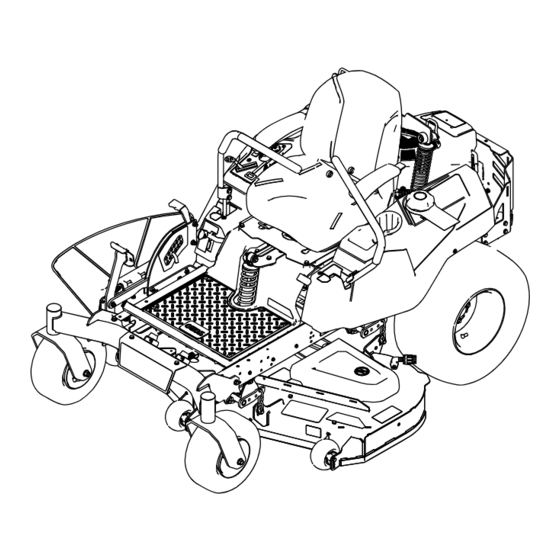

- Page 1 Form No. 3424-960 Rev C TimeCutter ® HD MyRide 48in Riding Mower Model No. 75210—Serial No. 404314000 and Up *3424-960* Register at www.Toro.com. Original Instructions (EN)

-

Page 2: Figure 1

Authorized Service Go to www.Toro.com to view specifications on your Dealer or Toro Customer Service and have the model model. and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers The enclosed engine owner's manual is supplied on the product. -

Page 3: Table Of Contents

Contents Servicing the Fuses .......... 40 Drive System Maintenance ........41 Checking the Tire Pressure....... 41 Safety ............... 4 Belt Maintenance ..........41 Safety Alert Symbol ..........4 Inspecting the Belts .......... 41 General Safety ........... 4 Replacing the Mower Belt ......... 41 Slope Indicator ........... -

Page 4: Safety

Safety This machine is capable of amputating hands and feet The following instructions are from ANSI standard and of throwing objects. Toro designed and tested B71.1-2017. this lawn mower to offer reasonably safe service; however, failure to comply with safety instructions may result in injury or death. -

Page 5: Slope Indicator

Slope Indicator g011841 Figure 3 You may copy this page for personal use. 1. The maximum slope you can operate the machine on is 15 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope. -

Page 6: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decaloemmarkt Manufacturer's Mark 1. Indicates the blade is identified as a part from the original machine manufacturer. - Page 7 decal132-0872 132-0872 1. Thrown object 3. Severing hazard of hand hazard—keep bystanders or foot—keep away from away from the machine. moving parts. 2. Thrown object hazard, 4. Entanglement raised deflector—do not hazard—keep away operate the machine with from moving parts; keep an open deck;...

- Page 8 decal136-4245 136-4245 1. Slow 3. Fast 2. Transport decal136-5596 136-5596 1. Check the tire pressure 4. Check the tire pressure every 25 operating hours. every 25 operating hours. 2. Engine oil 5. Read the Operator's Manual before performing maintenance. 3. Check the tire pressure every 25 operating hours.

- Page 9 decal132-0869 132-0869 Note: This machine complies with the industry standard stability test in the static lateral and longitudinal tests with the maximum recommended slope indicated on the decal. Review the instructions for operating the machine on slopes in the Operator’s Manual as well as the conditions in which you would operate the machine to determine whether you can operate the machine in the conditions on that day and at that site.

- Page 10 decal133-9263 133-9263 1. Fast 4. PTO disengage 2. Slow 5. PTO engage 3. Choke...

-

Page 11: Product Overview

Controls Product Overview Become familiar with all the controls before you start the engine and operate the machine. Control Panel g188738 Figure 5 1. Hour meter 4. Key switch 2. Throttle control 5. Blade-control switch g207189 Figure 4 (power takeoff) 3. -

Page 12: Eutral Lock

To ensure optimum performance and continued safety and raise the deck from the seated position. You certification of the machine, use only genuine Toro can use the foot pedal to lift the deck briefly to avoid replacement parts and accessories. Replacement... -

Page 13: Before Operation

Only use accessories and Refer to the Maintenance section and perform all the attachments approved by Toro. necessary inspection and maintenance steps. • Inspect the area where the equipment is to be used and remove all rocks, toys, sticks, wires, bones, and other foreign objects. -

Page 14: Fuel Safety

Fuel Safety DANGER In certain conditions during fueling, static Use extreme care when handling fuel. electricity can be released causing a spark which can ignite gasoline vapors. A fire or DANGER explosion from gasoline can burn you and In certain conditions gasoline is extremely others and cause property damage. -

Page 15: Adding Fuel

Adding Fuel Recommended Fuel • For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method). • Ethanol: Gasoline with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. -

Page 16: Using The Safety-Interlock System

Using the Safety-Interlock and rise slightly from the seat; the engine should shut off. System Sit on the seat, engage the parking brake, move the blade-control switch (PTO) to the O position, and move the motion-control levers WARNING to N position. -

Page 17: Adjusting The Myride™ Suspension System

Adjusting the MyRide™ Adjust the rear-shock assemblies (Figure 10). Suspension System The MyRide™ suspension system adjusts to provide a smooth and comfortable ride. You can adjust the rear 2-shock assemblies to quickly and easily change the suspension system. Position the suspension system where you are most comfortable. -

Page 18: During Operation

During Operation • Be sure all drives are in neutral and parking brake is engaged before starting engine. • Start the engine carefully according to instructions During Operation Safety with feet well away from the blades. • Never operate the mower with damaged guards, General Safety shields, or covers. - Page 19 – Whenever you leave the mower. Do Not leave distance (twice the width of the machine) between a running machine unattended. the machine and any hazard. Use a walk behind machine or a hand trimmer to mow the grass in •...

-

Page 20: Entering The Operator's Position

Entering the Operator’s Disengaging the Parking Brake Position To disengage the parking brake, pull the lever out of the detent slot and toward you, then push it down (Figure 14). Use the mower deck as a step to get into the operator’s position (Figure 12). -

Page 21: Operating The Throttle

Operating the Choke Use the choke to start a cold engine. Pull up the choke knob to engage the choke before using the key switch (Figure 19). Push down the choke knob to disengage the choke after the engine has started (Figure 19). -

Page 22: Operating The Key Switch

Operating the Key Switch Starting the Engine Turn the key to the S position (Figure 20). TART Note: A warm or hot engine may not require choking. Note: When the engine starts, release the key. Important: Do not engage the starter for more than 5 seconds at a time. -

Page 23: Using The Motion-Control Levers

Driving the Machine CAUTION Children or bystanders may be injured if they The drive wheels turn independently, powered by move or attempt to operate the machine while hydraulic motors on each axle. You can turn 1 side it is unattended. in reverse while you turn the other forward, causing the machine to spin rather than turn. -

Page 24: Using The Smart Speed Tm Control System

Using the Smart Speed Control System The Smart Speed Control-System lever, located to the right of the operating position (Figure 25), gives you a choice to drive the machine at 3 ground speed ranges—trim, tow, and mow. g197125 Figure 25 1. -

Page 25: Using The Side Discharge

Adjusting the Height of Cut This is the medium speed. The suggested uses for The machine is equipped with a foot pedal deck-lift this speed are as follows: system. You can use the foot pedal to lift the deck briefly to avoid obstacles or lock the deck in the •... -

Page 26: Adjusting The Anti-Scalp Rollers

Adjusting the Anti-Scalp Select a hole in the height-of-cut system corresponding to the desired height of cut and Rollers insert the pin (Figure 27). Push on the deck-lift pedal with your foot and Whenever you change the height of cut, adjust the pull the handle rearward to disengage the height of the anti-scalp rollers. -

Page 27: Using Attachments And Accessories

Using Attachments and Operating Tips Accessories Using the Fast Throttle Setting Use only Toro approved attachments and accessories. For best mowing and maximum air circulation, operate the engine at the F position. Air is required to If you attach a bucket to the engine guard, use a strap thoroughly cut grass clippings, so do not set the to secure it. -

Page 28: After Operation

Tighten sharpen the blades as necessary. If a blade is loose hardware. damaged or worn, replace it immediately with a genuine Toro replacement blade. Transporting Transporting the Machine Use a heavy-duty trailer or truck to transport the machine. - Page 29 on the down side of the slope and the ramp extends up the slope. This will minimize the ramp angle. WARNING Loading a machine onto a trailer or truck increases the possibility of tip-over and could cause serious injury or death. •...

- Page 30 and loss of control. Reduce the towed weight and slow down. • Stopping distance increases with the weight of the towed load. Travel slowly and allow extra distance to stop. • Make wide turns to keep the attachment clear of the machine.

-

Page 31: Pushing The Machine By Hand

Pushing the Machine by Operating the Machine Hand Move the bypass levers rearward through the keyhole and down to lock them in place as shown in Figure Important: Always push the machine by hand. Do Note: Do this for each lever. not tow the machine, because damage may occur. -

Page 32: Maintenance

Unauthorized modifications to the original equipment or Maintenance Safety failure to use original Toro parts could lead to serious injury or death. Unauthorized WARNING changes to the machine, engine, fuel or... -

Page 33: Recommended Maintenance Schedule(S)

Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Change the engine oil. After the first 8 hours • Check the safety-interlock system. • Clean and check the air-cleaner element. • Check the engine-oil level. Before each use or daily •... -

Page 34: Engine Maintenance

Engine Maintenance Servicing the Paper Air-Cleaner Element Engine Safety Service Interval: Every 100 hours—Clean the paper air-cleaner element (more often in • Shut off the engine before checking the oil or dirty or dusty conditions). adding oil to the crankcase. Every 200 hours—Replace the paper air-cleaner •... - Page 35 Checking the Engine-Oil Level Changing the Engine Oil Service Interval: Before each use or daily Service Interval: After the first 8 hours—Change the engine oil. Note: Check the oil when the engine is cold. Every 100 hours—Change the engine oil (more Important: If you overfill or underfill the engine often in dirty or dusty conditions).

- Page 36 Changing the Engine-Oil Filter Service Interval: Every 200 hours—Change the engine-oil filter (more often in dirty or dusty conditions). Drain the oil from the engine; refer to Changing the Engine Oil (page 35). Change the engine-oil filter (Figure 38). g235264 Figure 37 Dispose of the used oil at a recycling center.

-

Page 37: Servicing The Spark Plug

Servicing the Spark Plug Service Interval: Every 100 hours Ensure that the air gap between the center and side electrodes is correct before installing the spark plug. Use a spark plug wrench for removing and installing the spark plug and a gapping tool or feeler gauge to check and adjust the air gap. -

Page 38: Fuel System Maintenance

Fuel System Maintenance DANGER g027590 In certain conditions, fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property. Refer to Adding Fuel (page 15) for a complete list of fuel related precautions. Replacing the In-Line Fuel Filter Service Interval: Every 100 hours—Replace the... -

Page 39: Electrical System Maintenance

Electrical System Maintenance Electrical System Safety • Disconnect the battery before repairing the machine. Disconnect the negative terminal first and the positive last. Connect the positive terminal first and the negative last. • Charge the battery in an open, well-ventilated g190587 area, away from sparks and flames. -

Page 40: Servicing The Fuses

Charging the Battery Servicing the Fuses Service Interval: Before storage—Charge the battery The electrical system is protected by fuses. It requires and disconnect the battery cables. no maintenance; however, if a fuse blows, check the component/circuit for a malfunction or short. Remove the battery from the chassis;... -

Page 41: Drive System Maintenance

Remove the floor pan to access the idler pulley. Using a spring removal tool, (Toro Part No. 92-5771), remove the idler spring from the deck post to remove tension on the idler pulley (Figure 49). -

Page 42: Mower Maintenance

Be careful when removing the belt. Inspecting the Blades Using a spring-removal tool, (Toro Part No. Service Interval: Before each use or daily 92-5771), install the idler spring over the deck post and placing tension on the idler pulley and... - Page 43 g006530 Figure 50 1. Cutting edge 3. Wear/slot forming g014973 Figure 52 2. Curved area 4. Crack 1. Blade (in position for measuring) 2. Level surface Checking for Bent Blades 3. Measured distance between blade and the surface (A) Note: The machine must be on a level surface for Rotate the same blade 180 degrees so that the following procedure.

- Page 44 Removing the Blades Replace the blades if they hit a solid object, or if the blade is out of balance or bent. Hold the blade end using a rag or thickly padded glove. Remove the blade bolt, curved washer, and blade from the spindle shaft (Figure 55).

-

Page 45: Leveling The Mower Deck

Leveling the Mower Deck Check to ensure that the mower deck is level any time you install the mower or when you see an uneven cut g000553 on your lawn. Figure 57 Check the mower deck for bent blades prior to 1. - Page 46 Checking the Front-to-Rear Blade Leveling the Mower Deck Slope Set the anti-scalp rollers to the top holes or remove them completely for this procedure; refer Check the front-to-rear blade level any time you install Adjusting the Anti-Scalp Rollers (page 26). the mower.

-

Page 47: Removing The Mower Deck

g028276 Figure 63 1. Link pin 3. Hairpin cotter 2. Washer Lift up the mower deck to relieve tension from the mower deck. Remove the chains from the hooks on the g024313 Figure 62 deck-lift arms (Figure 64). 1. Deck-lift arm 3. -

Page 48: Installing The Mower Deck

Installing the Mower Deck Replacing the Grass Deflector Park the machine on a level surface, disengage the blade-control switch (PTO), and engage the parking brake. Service Interval: Before each use or daily—Inspect the grass deflector for damage. Shut off the engine, remove the key, and disconnect the spark-plug wires from the spark WARNING plugs. -

Page 49: Cleaning

Cleaning Position the spring on the rod as shown in Figure so that the shorter spring end comes from under the rod before the bend and going over Washing the Underside of the rod as it returns from the bend. Lift the loop end of the spring and place it into the Mower the notch on the deflector bracket... -

Page 50: Cleaning The Suspension System

Storage Sit on the seat and start the engine. Engage the blade-control switch and let the mower run for 1 to 3 minutes. Storage Safety Disengage the blade-control switch (PTO), shut off the engine, remove the key from the key •... -

Page 51: Storing The Battery

Storing the Battery use an alcohol-based stabilizer (ethanol or methanol). Fully charge the battery. Run the engine to distribute conditioned fuel Let the battery rest for 24 hours, then check the through the fuel system for 5 minutes. battery voltage. Shut off the engine, allow it to cool, and drain the fuel tank. -

Page 52: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The fuel tank is showing signs of collapsing 1. The air-cleaner paper element clogged. 1. Clean the paper element. or the machine is frequently showing signs of running out of fuel. The engine overheats. 1. - Page 53 Problem Possible Cause Corrective Action The machine does not drive. 1. The bypass valves are open. 1. Close the tow valves. 2. The traction belts are worn, loose, or 2. Contact an Authorized Service Dealer. broken. 3. The traction belts are off the pulleys. 3.

-

Page 54: Schematics

Schematics g289095 Electrical Diagram (Rev. A) - Page 55 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.