Summary of Contents for Beko BM33U

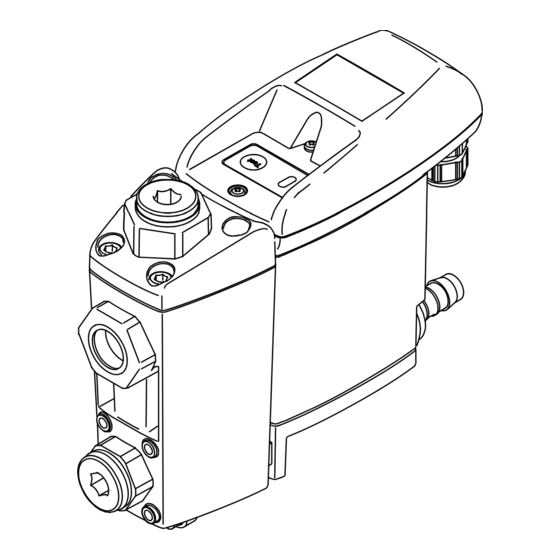

- Page 1 EN - english Instructions for installation and operation Condensate drain ® BEKOMAT 33U / 33U CO (BM33U / BM33UCO)

- Page 2 Dear customer, Thank you for deciding in favour of the BEKOMAT ® 33U / 33U CO condensate drain. Please read the installation and operating instructions carefully before mounting and starting up the BEKOMAT ® 33U / 33U CO , and follow our directions. Perfect functioning of the BEKOMAT ®...

-

Page 3: Table Of Contents

Pictograms and symbols ........................4 Safety instructions ..........................4 Proper use .............................. 6 Exclusion from the scope of application ....................6 Technical data ............................7 Electrical data ............................8 ... -

Page 4: Pictograms And Symbols

Pos: 7 /Beko Technische Dokumentation/Globale Texte/Allgemeiner Hinweis BM @ 0\mod_1183615737313_2901.docx @ 4006 @ @ 1 Pos: 8 /Beko Technische Dokumentation/Sicherheit/Hinweis Anleitung BEKO (männl. Name) @ 0\mod_1184147787557_2901.docx @ 5760 @ @ 1 Please check whether or not these instructions correspond to the device type. - Page 5 The removed control unit has no IP degree of protection. • All types of electrical works must be carried out by authorised and qualified personnel only. Pos: 13 /Beko Technische Dokumentation/Sicherheit/Sicherheitshinweise, weitere BM (nicht Ex, nicht IF) @ 0\mod_1183616103770_2901.docx @ 4011 @ @ 1 Further safety instructions: •...

-

Page 6: Proper Use

® 33U / 33U CO must not be installed and operated in areas with an aggressive atmosphere. Pos: 23 /Beko Technische Dokumentation/Bestimmungsgemäße Verwendung/BEKOMAT/Ausschluß Anwendung BM nicht für frostgefährdete Bereiche (Zusatz) @ 0\mod_1216106439206_2901.docx @ 11234 @ @ 1 ® • The BEKOMAT 33U / 33U CO is not heatable and, therefore, not suitable for the use in areas where frost is likely to occur. -

Page 7: Technical Data

Pos: 25 /Beko Technische Dokumentation/Überschriften/1/Technische Daten @ 0\mod_1184329570967_2901.docx @ 6058 @ 1 @ 1 Technical data Pos: 26 /Beko Technische Dokumentation/Technische Daten/BEKOMAT/Techn. Daten BM 3xU + UC + GOST +Fcc (o.Leistg.) @ 5\mod_1358843578945_2901.docx @ 30450 @ @ 1 0,8...16 bar (12...230 psi) min./max. -

Page 8: Electrical Data

Pos: 29 /Beko Technische Dokumentation/Überschriften/1/Elektrische Daten @ 0\mod_1183638451371_2901.docx @ 5601 @ 1 @ 1 Electrical data Pos: 30 /Beko Technische Dokumentation/Elektrische Daten/BEKOMAT/Elektrische Daten BM 32U/33U @ 4\mod_1357737405732_2901.docx @ 29582 @ @ 1 95…240 VAC ±10% (50…60 Hz) /100…125 VDC ±10%... -

Page 9: Dimension Drawing

198 (7.79) 8 Nm 0,9 ± 0,1 Nm Pos: 34 /Beko Technische Dokumentation/Technische Daten/Masszeichnung Ergänzung SW @ 1\mod_1250153244115_2901.docx @ 15481 @ @ 1 SW = wrench size Pos: 35 /---- Seitenumbruch ---- @ 0\mod_1157028099015_0.docx @ 2903 @ @ 1 BEKOMAT® 33U / 33U CO... -

Page 10: Climate Zones And Performance Data

Climate zones and performance data Pos: 36 /Beko Technische Dokumentation/Überschriften/1/Klimazonen und Leistungsdaten @ 0\mod_1183638385480_2901.docx @ 5583 @ 1 @ 1 Climate zones and performance data Pos: 37 /Beko Technische Dokumentation/Klimazonen/Klimazonen BM @ 0\mod_1184573462796_2901.docx @ 6180 @ @ 1 Max. Max. -

Page 11: Function

When the BEKOMAT 33U / 33U CO is empty, the outlet line is reclosed tightly in time before unnecessary compressed-air losses occur. Pos: 41 /Beko Technische Dokumentation/Funktion/BEKOMAT/BM 32U/33U LED-Taster-Funktion @ 4\mod_1354691493582_2901.docx @ 29040 @ @ 1 BEKOMAT® 33U / 33U CO... - Page 12 Blocked / obstructed outlet line • Extreme amount of dirt particles • Frozen pipework Pos: 43 /Beko Technische Dokumentation/Funktion/BEKOMAT/BM 31U/32U/33U+Vario Abl.-Wartungsmeldg. aktiv (nicht 32U FMK + IF) Wartungsintervall @ 5\mod_1371731964818_2901.docx @ 31020 @ @ 1 BEKOMAT® 33U / 33U CO...

- Page 13 Function ® The BEKOMAT 33U / 33U CO releases a maintenance message for a service that is to be carried out. Depending on the operating mode, a visual maintenance message (service) is activated which signalises the replacement of the service unit. The maintenance message is indicated by the flashing supply voltage-LED "Power".

-

Page 14: Installation

Risk of serious injury or death through contact with quickly or suddenly escaping compressed air or through bursting plant components or plant components which are not secured. Pos: 47 /Beko Technische Dokumentation/Sicherheit/Maßnahmen Druckluft BM @ 0\mod_1184148284291_2901.docx @ 5814 @ @ 1 Measures: •... - Page 15 Installation Pos: 50 /Beko Technische Dokumentation/Sicherheit/Hinweis Vorschriften Werkzeug Reinigung Kondensat Entsorgung @ 0\mod_1233239666823_2901.docx @ 13340 @ @ 1 Note: It is imperative to observe all hazard statements and warnings listed here. Please also observe all regulations and notes regarding industrial safety and fire prevention at the place of installation.

- Page 16 Installation wrong correct Pressure differences! Each condensate accumulation point must be drained separately. Continuous slope! Avoid a water pocket when installing the feed pipe Deflector area! If drainage is to be carried out directly from the pipe, deflection of the air flow will be useful. Ventilation! If the slope in the inlet line is not sufficient or if any other inflow problems occur, a venting line needs...

-

Page 17: Electrical Installation

Electrical installation Pos: 53 /Beko Technische Dokumentation/Überschriften/1/Elektrische Installation @ 0\mod_1183638507355_2901.docx @ 5619 @ 1 @ 1 11 Electrical installation Pos: 54 /Beko Technische Dokumentation/Sicherheit/Gefahr Netzspannung 1 s/w @ 0\mod_1184148186948_2901.docx @ 5796 @ @ 1 Danger! Supply voltage! There is the risk of an electric shock involving injury or death when coming into contact with non-insulated components carrying supply voltage. - Page 18 Electrical installation Connection of the potential-free contact and of the external test: 1. Selection of the suitable cable. 2. Connection to X2 and X3, as shown in the adjacent illustration. 3. The installation steps are the same as for the power supply connection. 4.

- Page 19 Electrical installation Pos: 57 /Beko Technische Dokumentation/Installation/BEKOMAT/Klemmenbelegung BM 32U/33U @ 4\mod_1354692952721_2901.docx @ 29108 @ @ 1 Terminal assignment supply voltage (operating voltage) Power supply • X 1.1 L/+ • X 1.2 N/- L = Outer conductor N = Neutral conductor...

- Page 20 At a low-voltage supply (< 50 VAC / < 75 VDC), only use a protective extra-low-voltage. Tighten the threaded cable connection with a slightly sealing effect. Pos: 58 /Beko Technische Dokumentation/Installation/BEKOMAT/E-Schema @ 0\mod_1233758178163_2901.docx @ 13497 @ @ 1 +24 VDC X1.1...

-

Page 21: Inspection And Maintenance

Inspection and maintenance Pos: 60 /Beko Technische Dokumentation/Überschriften/1/Kontrolle und Wartung @ 0\mod_1183637885371_2901.docx @ 5439 @ 1 @ 1 12 Inspection and maintenance Pos: 61 /Beko Technische Dokumentation/Sicherheit/Gefahr Druckluft @ 0\mod_1184148143854_2901.docx @ 5778 @ @ 1 Danger! Compressed air! Risk of serious injury or death through contact with quickly or suddenly escaping compressed air or through bursting plant components or plant components which are not secured. - Page 22 Inspection and maintenance Pos: 68 /Beko Technische Dokumentation/Sicherheit/Hinweis Vorschriften Werkzeug Reinigung Kondensat Entsorgung @ 0\mod_1233239666823_2901.docx @ 13340 @ @ 1 Note: It is imperative to observe all hazard statements and warnings listed here. Please also observe all regulations and notes regarding industrial safety and fire prevention at the place of installation.

- Page 23 Inspection and maintenance 13 12 BEKOMAT® 33U / 33U CO...

- Page 24 Inspection and maintenance 9. Insert new cover O-ring (18) gasket kit) according to the diagram. 10. C lean the sealing surfaces of the cover. 11. P ut on the cover (17) with the new O-ring and carefully tighten the four cover screws (16) crosswise (8 Nm).

- Page 25 Inspection and maintenance 13. C heck whether or not the service unit (9) goes with the control unit (1) (model designation and colour of the arresting hook). 14. C heck the O-rings at the new service unit (12, 13). 15. M ount the design shell (11). 16....

- Page 26 Inspection and maintenance ® Installation of the control unit on the BEKOMAT 1. Check whether or not the service unit (9) goes with the control unit (1) (model designation and colour of the arresting hook). 2. Check whether or not the sealing mat (8) and the contact springs (28) are clean, dry, and free from impurities.

-

Page 27: Troubleshooting And Fault Elimination

Troubleshooting and fault elimination Pos: 71 /Beko Technische Dokumentation/Überschriften/1/Fehlersuche und Fehlerbehebung @ 0\mod_1183637945027_2901.docx @ 5457 @ 1 @ 1 13 Troubleshooting and fault elimination Pos: 72 /Beko Technische Dokumentation/Fehlersuche/BEKOMAT/Fehlersuche BM 32U/32UV/32U FM(K)/33U/33UV @ 4\mod_1357742330741_2901.docx @ 29650 @ @ 1 Symptoms... -

Page 28: Elements And Components

Pos: 74 /Beko Technische Dokumentation/Überschriften/1/Bauteile und Komponenten @ 0\mod_1183638014355_2901.docx @ 5475 @ 1 @ 1 14 Elements and components Pos: 75 /Beko Technische Dokumentation/Bauteile und Komponenten/BEKOMAT/Bauteile BM 33U (nicht Vario) @ 4\mod_1358417934032_2901.docx @ 30000 @ @ 1 1 Screw 3.5 x 10... -

Page 29: Accessories

Accessories Pos: 79 /Beko Technische Dokumentation/Überschriften/1/Zubehör @ 0\mod_1232362905455_2901.docx @ 13030 @ 1 @ 1 16 Accessories Pos: 80 /Beko Technische Dokumentation/Ersatzteile Verbrauchsmaterialien Zubehör/BEKOMAT/Haltewinkel BM 33/ BM 33U @ 0\mod_1233244627657_2901.docx @ 13367 @ @ 1 Available accessory sets Contents Order number... -

Page 30: Declaration Of Conformity

Declaration of conformity Pos: 83 /Beko Technische Dokumentation/Überschriften/1/Konformitätserklärung @ 0\mod_1210752269256_2901.docx @ 8060 @ 1 @ 1 17 Declaration of conformity Pos: 84 /Beko Technische Dokumentation/Zertifikate/Erklärungen/BEKOMAT/BEKOMAT 31U-33U-EG-KonformScan @ 5\mod_1358418648413_0.docx @ 30238 @ @ 1 Pos: 85 /---- Seitenumbruch ---- @ 0\mod_1157028099015_0.docx @ 2903 @ @ 1... - Page 31 Christian Riedel Head of International Quality Management Pos: 87 /Beko Technische Dokumentation/Globale Texte/Hinweis Übersetzg. d. Orig.anleitg. @ 1\mod_1260433478358_2901.docx @ 17104 @ @ 1 Pos: 88 /Beko Technische Dokumentation/Globale Texte/Hinweis Originalanleitung @ 1\mod_1260433346280_2901.docx @ 17070 @ @ 1 Pos: 89 /Beko Technische Dokumentation/Globale Texte/Vorbehaltsklausel @ 0\mod_1213704033153_2901.docx @ 9298 @ @ 1 === Ende der Liste für Textmarke Inhalt ===...

- Page 32 Installation and operating instructions 4 A Instructions, safety instructions 4 Accessories 29 Intermediate adapter 28 Accessory sets 29 L Alarm mode 12 Angle adapter 28 Lower part of the cover 28 B M blows off 27 Maintenance 21 Both LEDs are continuously on 27 Maintenance recommendation 22 Malfunction 27 C ...

- Page 33 W Water pocket 16 BEKOMAT® 33U / 33U CO...

- Page 34 BEKOMAT® 33U / 33U CO...

- Page 35 BEKOMAT® 33U / 33U CO...

- Page 36 Italia / Italy Polska / Poland 日本 / Japan BEKO TECHNOLOGIES S.r.l BEKO TECHNOLOGIES Sp. z o.o. BEKO TECHNOLOGIES K.K Via Peano 86/88 ul. Pańska 73 KEIHIN THINK Building 8 Floor I - 10040 Leinì (TO) PL - 00-834 Warszawa 1-1 Minamiwatarida-machi Tel.