Summary of Contents for Baroness LM18GC

- Page 1 Walk Behind Greens Mower Walk Behind Tee Mower Owner's Operating Manual Serial No. LM18GC: 35165-・LM56GC: 36481- LM66TC: 35329- "Required reading" Read this manual before using the machine. Ver.2.8...

- Page 2 LM18GC・LM56GC / LM66TC Regulations USDA Forest Service Spark Arrester (For USA) The engine of this machine is equipped with a spark arrester. In some areas there are local, state, or federal regulations requiring that a spark arrester be used on the engine of this machine.

- Page 3 LM18GC・LM56GC / LM66TC Greeting Thank you for purchasing the Baroness product. LM56GC: https://doc.baroness- This manual describes the proper handling, international.com/manuals/LM56GC adjustment, and inspection of your product. LM56GC-0901Z0 We hope you will use the product safely, and take QR code LM56GC advantage of its best performance.

- Page 4 The operator is responsible for operating the product properly and safely. Maintenance service for this machine should be performed by a mechanic with expertise. If you have any questions concerning maintenance or genuine parts, please contact a Baroness dealer or Kyoeisha.

- Page 5 When replacing parts, be sure to use genuine Baroness parts or parts designated by Kyoeisha. Note that the Baroness product warranty may not apply to defects caused by the use of parts from other companies. Prior to use, carefully read the following manuals to thoroughly understand the contents for safe and correct operation.

- Page 6 LM18GC・LM56GC / LM66TC Introduction...

-

Page 7: Table Of Contents

LM18GC・LM56GC / LM66TC Contents Safety .............. Page 1-1 Storage ............Page 6-25 Repair ..............Page 7-1 Safe Operating Practices .......Page 1-2 Disposal ............Page 2-1 Precautions for Repair ........Page 7-2 Adjustment and Replacement ......Page 7-2 Recycle and Waste Disposal ......Page 2-2 Appended Table .......... - Page 8 LM18GC・LM56GC / LM66TC Contents...

-

Page 9: Safety

LM18GC・LM56GC / LM66TC Safety Safe Operating Practices ...... Page 1-2 Training ..........Page 1-2 Preparation ..........Page 1-2 Operation ..........Page 1-3 Maintenance .......... Page 1-4 Storage ..........Page 1-4 Page 1-1... -

Page 10: Safe Operating Practices

LM18GC・LM56GC / LM66TC Safety Failure to adequately follow these safety Preparation precautions may cause an accident resulting in injury or death. Evaluate the terrain to determine what accessories and attachments are needed to Danger Danger properly and safely perform the job. -

Page 11: Operation

LM18GC・LM56GC / LM66TC Safety If the handlebar has noticeable play, be sure Remember there is no such thing as a safe to adjust or repair them before operating the slope. machine. Travel on grass slopes requires particular care. Replace faulty mufflers. -

Page 12: Maintenance

LM18GC・LM56GC / LM66TC Safety Take care when loading or unloading the Keep all nuts, bolts and screws tight to be machine into a trailer or a truck. sure the equipment is in safe working Load or unload the machine in a flat and condition. -

Page 13: Disposal

LM18GC・LM56GC / LM66TC Disposal Recycle and Waste Disposal ....Page 2-2 About Recycle ........Page 2-2 About Waste Disposal ......Page 2-2 Page 2-1... -

Page 14: Recycle And Waste Disposal

LM18GC・LM56GC / LM66TC Disposal Recycle and Waste Disposal About Recycle Recycling battery etc. is recommended for environmental conservation and economical use of resources. It may be required by local laws. About Waste Disposal Make sure that waste generated when servicing or repairing the machine is disposed of in accordance with local regulations. -

Page 15: Product Overview

LM18GC・LM56GC / LM66TC Product Overview Specifications ........Page 3-2 Specifications List ........Page 3-2 Sound Pressure Level ......Page 3-8 Sound Power Level ....... Page 3-8 Vibration Level ........Page 3-8 Names of Each Section ......Page 3-9 Regulation Decals ........Page 3-9 Positions of Regulation Decals .... -

Page 16: Specifications

LM18GC・LM56GC / LM66TC Product Overview Specifications Specifications List LM18GC Model LM18GC Name Walk Behind Greens Mower with grass Total length 141 cm 55.51 in catcher without Dimensions Total width travelling 84 cm 33.07 in wheel Steering Total height 116 cm 45.67 in... - Page 17 LM18GC・LM56GC / LM66TC Product Overview The factory default maximum engine rpm is 3,300 rpm. Weight (Machine) includes parts. The indicated lowest mowing height is for general application. It may be adjusted according to the state of green and the bed knife to be installed.

- Page 18 LM18GC・LM56GC / LM66TC Product Overview LM56GC Model LM56GC Name Walk Behind Greens Mower with grass Total length 141 cm 55.51 in catcher without Dimensions Total width travelling 94 cm 37.01 in wheel Steering Total height 116 cm 45.67 in handle...

- Page 19 LM18GC・LM56GC / LM66TC Product Overview The indicated lowest mowing height is for general application. It may be adjusted according to the state of green and the bed knife to be installed. The value in the brackets [ ] is the mowing height of the machine equipped with a groomer.

- Page 20 LM18GC・LM56GC / LM66TC Product Overview LM66TC Model LM66TC Name Walk Behind Tee Mower Total with grass catcher 141 cm 55.51 in length Total Dimensions without travelling wheel 103 cm 40.55 in width Total Steering handle 116 cm 45.67 in height...

- Page 21 LM18GC・LM56GC / LM66TC Product Overview The indicated lowest mowing height is for general application. It may be adjusted according to the state of green and the bed knife to be installed. The value in the brackets [ ] is the mowing height of the machine equipped with a groomer.

-

Page 22: Sound Pressure Level

LM18GC・LM56GC / LM66TC Product Overview Sound Pressure Level Vibration Level LM18 LM18 Sound Pressure Level Hand-Arm Vibration ■ ■ This machine was confirmed to have a This machine was confirmed not to exceed a continuous A-weighted sound pressure level vibration level of 2.5 m/s... -

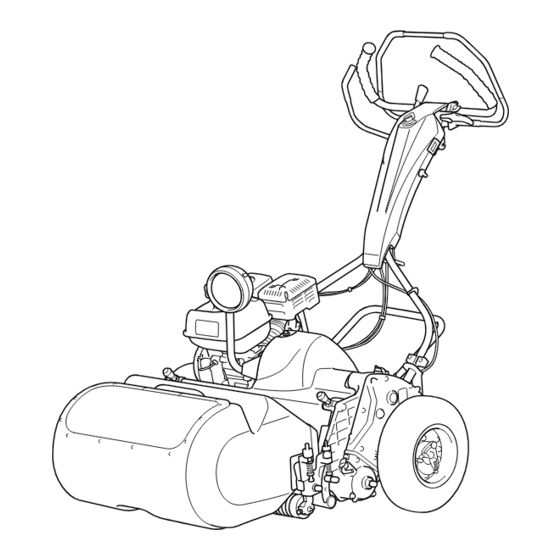

Page 23: Names Of Each Section

LM18GC・LM56GC / LM66TC Product Overview Names of Each Section Regulation Decals Positions of Regulation Decals quwxcl-209 Positions of Regulation Decals_001 Serial number plate Spark arrester warning decal California Proposition 65 decal (walk quwxcl-208 behind type) Names of Each Section_001 Description of Regulation Decals... - Page 24 LM18GC・LM56GC / LM66TC Product Overview Spark Arrester Warning Decal (For the State of California, USA) Spark arrester warning decal describes the warning messages as required by California Public Resources Code. bfaymx-001 Spark Arrester Warning Decal_001 California Proposition 65 Decal (Walk Behind...

-

Page 25: Safety Signs And Instruction Signs

If they are damaged, become dirty, or peel off, replace them with new ones. Part numbers for decals that need to be replaced are listed in the parts catalog. Order them from a Baroness dealer or Kyoeisha. Positions of Safety Decals and Instruction Decals... - Page 26 LM18GC・LM56GC / LM66TC Product Overview Caution to Mutilation Decal Greasing Each 10-Hours Decal K4205001600 K4209000370 DECAL, CAUTION TO MUTILATION DECAL, GREASING EACH 10-HOURS Add grease every 10 hours. Warning May cut your hand or leg - Stop the cutter rotation and engine. Otherwise you may get injured.

-

Page 27: Operation Decals

LM18GC・LM56GC / LM66TC Product Overview Description of Operation Decals Operation Decals Engine Switch Mark Positions of Operation Decals ENGINE SWITCH MARK It illustrates the positions of the engine switch. rcyo1p-003 Engine Switch Mark_001 High / Low Selector Lever Decal K4203001320... - Page 28 LM18GC・LM56GC / LM66TC Product Overview Clutch Decal Light Switch Mark K4203001110 Note: STICKER, CLUTCH Depending on the specifications, this function This indicates operating positions (traveling/ may not be available. working) for the reel cutter (cutting cylinder) K4203001610 and drum. DECAL, LIGHT SWITCH It illustrates ON/OFF of the light.

-

Page 29: Description Of Functions

LM18GC・LM56GC / LM66TC Description of Functions Light Switch ........... Page 4-2 Engine Switch ........Page 4-2 Throttle Lever .........Page 4-2 Throttle Lever .........Page 4-2 Brake Lever ..........Page 4-3 Clutch Lock Lever ........Page 4-3 Main Clutch Lever ........Page 4-3 Traveling/Working Selector Lever ..Page 4-4 FOC (High/Low Clip) Selector Lever .. -

Page 30: Light Switch

LM18GC・LM56GC / LM66TC Description of Functions Light Switch Throttle Lever Note: Note: Depending on the specifications, this function Depending on the specifications, this function may not be available. may not be available. The light switch is located in the handle panel. -

Page 31: Brake Lever

LM18GC・LM56GC / LM66TC Description of Functions Brake Lever Caution Avoid quick operation. Carefully and slowly operate the machine. The brake lever is located in the handle. Grip the brake lever to activate braking and the travel of the machine is stopped. -

Page 32: Traveling/Working Selector Lever

LM18GC・LM56GC / LM66TC Description of Functions This is suitable for the work in good turf Traveling/Working Selector Lever condition. When the lever is set to the "Low clip" position, Caution the reel cutter (cutting cylinder) rotates slower compared to the "High clip” position, and the This lever should be operated while the main clip pitch becomes longer. -

Page 33: Air Adjusting Plate

LM18GC・LM56GC / LM66TC Description of Functions Air Adjusting Plate Caution The air adjusting plate should be operated while the engine rotation is stopped, and adjusted to the position suitable for your work. The air adjusting plate is attached on the reel cover. -

Page 34: Igca (Independent Grass Catcher Arm)

Depending on the specifications, this function the added weight of grass, thatch, sand, may not be available. etc. (IGCA can be installed onto the LM18GC/ The operator can mow at a uniform cutting LM56GC.) height from the start of mowing the green to IGCA is located above the cutting section. - Page 35 LM18GC・LM56GC / LM66TC Description of Functions Issue 2: IGCA The cutting height is uneven due to the up- Cutting section and-down movements of the cutting section Grass catcher caused by the operator's handle movements. Solution: Effect 2: The grass catcher and handle are linked,...

-

Page 36: Instruments

LM18GC・LM56GC / LM66TC Description of Functions Instruments Hour Meter Important The battery of this hour meter can not be replaced. If the battery power is burned out, replace the hour meter with a new one. The hour meter indicates the accumulated operation time of the engine. -

Page 37: Handling Instructions

LM18GC・LM56GC / LM66TC Handling Instructions Preparation for Use ....... Page 5-2 Removing/Installing Grass Catcher ..Page 5-13 Transporting .........Page 5-14 Installing The Handle ......Page 5-2 Connection of Engine Switch Cord ..Page 5-2 Transporting Procedure ....... Page 5-14 Installing The Stand ....... Page 5-2 Confirmation of The Operation .... -

Page 38: Preparation For Use

LM18GC・LM56GC / LM66TC Handling Instructions The crimp terminal is secured to the engine Preparation for Use crankcase with a hexagon bolt. Installing The Handle Put the handle pin on the left frame into the hole at the left-side lower edge of the handle. -

Page 39: Inspection And Cleaning

LM18GC・LM56GC / LM66TC Handling Instructions Tighten the bolt, washer, and nut at the left Make sure that the reel cutter (cutting side of the stand that were temporarily cylinder) and the bed knife (bottom blade) secured. are not cracked. Check to see how much the reel cutter (cutting cylinder) and the bed knife (bottom blade) are worn. -

Page 40: Roller

LM18GC・LM56GC / LM66TC Handling Instructions Make sure that the air cleaner element is Set the cover, and then secure it firmly with not contaminated. the wing screw. pd9d4r-015 Inspection of Air Cleaner_001 Air cleaner Cleaning of Air Cleaner Element A contaminated air cleaner elements may cause malfunction of the engine. -

Page 41: Drum

LM18GC・LM56GC / LM66TC Handling Instructions Drum Electrical Wiring Inspection of Drum Inspection of Electrical Wiring Make sure that the drum is not cracked or Important damaged. Electrical short circuit will cause fire, electrical Make sure that there is no abrasion or leakage and malfunction of electrical adhesion of the drum. -

Page 42: Engine Oil

LM18GC・LM56GC / LM66TC Handling Instructions Engine Oil Supply of Engine Oil Inspection of Engine Oil Important Do not supply too much engine oil. Otherwise, Important the engine may be damaged. Screw the oil level gauge firmly. Important Stop the engine, wait for 10 to 20 minutes for the engine to cool down, and then check Do not mix different types of engine oil. -

Page 43: Fuel

LM18GC・LM56GC / LM66TC Handling Instructions Fuel Inspection of Fuel Quantity Level the machine and then remove the tank cap to inspect fuel quantity from the fill port. 2e4emp-010 Fuel Supply_001 Fuel strainer Filling opening Maximum limit of fueling guc5f6-012 2.5 cm (0.98 in) -

Page 44: Adjustment Before Work

LM18GC・LM56GC / LM66TC Handling Instructions Dry with compressed air. Bolts and Nuts Inspection of Bolts and Nuts Important The bolts and nuts may be loosened at the earlier stage of the use. Be sure to retighten or replace before operating the machine whenever there is any abnormality. -

Page 45: Start/Stop Of Engine

LM18GC・LM56GC / LM66TC Handling Instructions Bolt Brake lever Conical spring washer Lock lever Washer Lock High Unlock Don't grip the main clutch lever. Start/Stop of Engine Procedure to Start Engine Caution Before starting the engine, make sure that there are no other people or obstacles around the machine. -

Page 46: Procedure To Stop Engine

LM18GC・LM56GC / LM66TC Handling Instructions Set the engine switch to the "ON" position. Pull the starter grip swiftly, and the engine will start. v2e27i-043 v2e27i-070 Procedure to Start Engine_005 Procedure to Start Engine_007 Engine switch Starter grip Recoil starter Set the choke lever to the "Open" position. -

Page 47: Parking And Stopping

LM18GC・LM56GC / LM66TC Handling Instructions Main clutch lever Caution Clutch lock lever Do not park the machine on a slope. Caution Set the engine switch to the "OFF" position. Check that the engine has stopped. Stop the machine on a flat place. -

Page 48: Cutting Work

LM18GC・LM56GC / LM66TC Handling Instructions Removal of traveling tires: Cutting Work Set the machine on its stand. Cutting Work Warning Do not operate on a steep slope. Caution Do not start to move or stop the machine abruptly. x9pzjh-001 Caution... - Page 49 LM18GC・LM56GC / LM66TC Handling Instructions Installation of traveling tires: Removing/Installing Grass Catcher Follow below steps to install the traveling tire. Caution Set the machine on its stand. Stop the engine before removing / installing Important the grass catcher. The drum shaft and traveling tire have Removing Grass Catcher: depressions and projections that fit together.

-

Page 50: Transporting

LM18GC・LM56GC / LM66TC Handling Instructions Transporting Transporting Procedure Caution When loading and unloading the machine, wear non-slip shoes and travel slowly. Important When securing the machine with a rope, do not tie the rope to the engine. Important When securing the machine with a rope, be careful not to bend any wires. -

Page 51: Maintenance

LM18GC・LM56GC / LM66TC Maintenance Precautions for Maintenance ....Page 6-2 Position of Mower during Maintenance ........... Page 6-2 Greasing ..........Page 6-2 About Greasing ........Page 6-2 Greasing Points ........Page 6-2 Lubrication ..........Page 6-4 About Lubrication ........Page 6-4 Lubricating Points ........Page 6-5 Adjustment and Replacement .... -

Page 52: Precautions For Maintenance

First, learn well the operations you plan to perform. Important Use tools appropriate for each operation. Important Use Baroness genuine parts for replacement and accessories. Our product warranty may be void if you use non-genuine parts for replacement or accessories. - Page 53 LM18GC・LM56GC / LM66TC Maintenance Differential gear No. of Greasing Location greasing period points Frame & Transmission 8 Differential gear Reel bearing Drum housing Front roller Groomer Refer to 8bq62b-247 "Maintenan Cam bush Greasing Points_004 Reel bearing Schedule." Before the initial greasing, remove the elastic...

-

Page 54: Lubrication

LM18GC・LM56GC / LM66TC Maintenance Front roller Cam bush There is one point each on the left and right. There is one point each on the right and left sides. Right side Apply 0.5 g (0.001 lb) of grease to outer perimeter of the cam bush pipe according to the maintenance schedule. -

Page 55: Lubricating Points

LM18GC・LM56GC / LM66TC Maintenance Throttle lever fulcrum Lubricating Points Note: Depending on the specifications, this There are oil filling ports at the following function may not be available. locations. Apply lubricant every 50 hours of operation. 9llqa9-043 Lubricating Points_003 Adjustment and Replacement... - Page 56 LM18GC・LM56GC / LM66TC Maintenance Important Adjust the right and left link rods so that they will be as long as each other. Remove the snap pin and washer and then remove the flat head pin. Loosen the nut A and turn the L-shape bracket to adjust the length of the link rod.

-

Page 57: Adjustment Of Blade Engagement

LM18GC・LM56GC / LM66TC Maintenance With the cutter adjustment nut, adjust the Adjustment of Blade Engagement engagement between the reel cutter (cutting cylinder) and the bed knife (bottom blade) so Caution that newspaper (one sheet) will be cleanly cut by the edge of both blades when the... -

Page 58: Adjustment Of Cutting Height

LM18GC・LM56GC / LM66TC Maintenance Adjustment of Cutting Height Important This applies the set cutting height that differs from the actual cutting height. Adjust the cutting height to fit your cutting work. Cutting Height and Blade Thickness of Bed Knife (Bottom Blade) - Page 59 LM18GC・LM56GC / LM66TC Maintenance Loosen the nut securing the roller adjuster. 33i8xn-002 3kws2a-014 Cutting Height and Blade Thickness of Bed Knife (Bottom Blade)_001 Adjustment of Front Roller_002 Standard blade Roller adjuster High-speed-steel-tipped blade Thickness of blade Position the cutting height gauge against...

-

Page 60: Adjustment Of Groomer

LM18GC・LM56GC / LM66TC Maintenance Again, make sure that the cutting height is Dethatching blade at the required position by positioning the Small screw for groomer setup cutting height gauge against the front roller Cutting height gauge and drum at the edge on the left and right Front roller sides of the mower unit. -

Page 61: Adjustment Of Cutter Adjustment Spring

LM18GC・LM56GC / LM66TC Maintenance Next time the groomer is used, loosen the Cutting height gauge right and left nuts, lower the groomer and Small screw for cutting height setup tighten the nuts so that it can return to the Fly nut groomer height set previously. -

Page 62: Adjusting Cam

LM18GC・LM56GC / LM66TC Maintenance Note: Adjusting CAM The figure below shows the situation when you see from the left side. Turn the cam bush on both sides of the bed The right side is mirror reversed. knife (bottom blade), and the blade can be raised and lowered respectively by maximum 0.3 mm (0.012 in). -

Page 63: Back Lapping

Caution Do not perform back lapping with any other persons. Have the following items ready: Strips of newspaper, Abrasive [Back lapping powder mixed with oil; or gel compound (Baroness genuine abrasive)], Brush. vjbj2l-001 Back Lapping_002 Traveling/Working selector lever Reel ON... - Page 64 LM18GC・LM56GC / LM66TC Maintenance Insert one or two strips of newspaper into the Connect the lapping machine or lapping space between the reel cutter (cutting handle to the lapping bolt of the machine. cylinder) and the bed knife (bottom blade) at an angle of 90 degrees.

-

Page 65: Sharpening Of Reel Cutter (Cutting Cylinder)

For sharpening the reel cutter (cutting cylinder), contact your dealer or Baroness unless you have a grinding machine. Caution Both the reel cutter (cutting cylinder) and the bed knife (bottom blade) are edged tools. -

Page 66: Replacement Of Reel Cutter (Cutting Cylinder)

LM18GC・LM56GC / LM66TC Maintenance Replacement of Reel Cutter (Cutting Reel cutter (cutting cylinder) blade Cylinder) Reel cutter (cutting cylinder) disc Reel cutter (cutting cylinder) shaft Caution Outer diameter of reel cutter (cutting cylinder) Both the reel cutter (cutting cylinder) and the Distance from blade edge to outer bed knife (bottom blade) are edged tools. - Page 67 LM18GC・LM56GC / LM66TC Maintenance Note: Important The outer diameter of the reel cutter (cutting cylinder) shaft is 25.4 mm (1.00 in). Use 30204JRP6 as bearing. Fill up the bearings and oil seals with grease (Excelite EP No. 2). Install the reel cutter (cutting cylinder) onto the frame.

-

Page 68: Replacement Of Bed Knife (Bottom Blade)

LM18GC・LM56GC / LM66TC Maintenance Reel gear Reel gear fixing nut Torque wrench 11.5 mm (0.453 in) Replacement of Bed Knife (Bottom Blade) Caution Both the reel cutter (cutting cylinder) and the d5gd5v-003 bed knife (bottom blade) are edged tools. Handle them carefully, since they could cut Replacement of Bed Knife (Bottom Blade)_002 your hands and feet. - Page 69 LM18GC・LM56GC / LM66TC Maintenance While supporting the bed knife base COMP, Cutter pin remove the cutter pins and lock nuts on Lock nut both sides. Cam bush Remove the bed knife base COMP. Remove the 2 bolts that secure the bed knife base arm Assy and bed knife base COMP.

- Page 70 LM18GC・LM56GC / LM66TC Maintenance Temporarily install the bed knife base Tighten the bolt used to install the bed knife COMP onto the machine with the left and base arm Assy, and then firmly secure it. right cutter pins and lock nuts.

- Page 71 LM18GC・LM56GC / LM66TC Maintenance Make sure that the bed knife (bottom blade) contacts the reel cutter (cutting cylinder). kx7caa-007 Installing The Bed Knife Base_007 kx7caa-005 Important Installing The Bed Knife Base_005 If one to five gap adjustment washers had Reel cutter (Cutting cylinder)

-

Page 72: Removing/Installing The Bed Knife

LM18GC・LM56GC / LM66TC Maintenance Align the vertical hole in the fulcrum seat, Removing/Installing The Bed Knife and then secure it. OK: The cutter adjustment bolt is centered Removing The Bed Knife in the hole of the fulcrum seat. NG: The cutter adjustment bolt is not Caution centered in the hole of the fulcrum seat. -

Page 73: Removing/Installing The Cover (Left)

LM18GC・LM56GC / LM66TC Maintenance Installing The Bed Knife Caution Both the reel cutter (cutting cylinder) and the bed knife (bottom blade) are edged tools. Handle them carefully, since they could cut your hands and feet. Caution 4miqko-002 Wear gloves when touching edged tools to Installing The Bed Knife_002 avoid cutting your hands. -

Page 74: Change Of Air Cleaner Element

LM18GC・LM56GC / LM66TC Maintenance Change of Air Cleaner Element Bolt S Washer Important Clutch retainer spring FOC (High/Low Clip) selector lever A contaminated air cleaner element may cause malfunction of the engine. Loosen the hexagon socket head bolt, and then remove the wheel driving fitting. -

Page 75: Storage

LM18GC・LM56GC / LM66TC Maintenance Remove the drain plug while the engine oil is Tire pneumatic pressure warm, and then drain the engine oil into a Set the tire air pressure slightly higher ・ bowl. than normal, and then place the machine Replace the drain plug in the engine. - Page 76 LM18GC・LM56GC / LM66TC Maintenance Page 6-26 Storage...

-

Page 77: Repair

LM18GC・LM56GC / LM66TC Repair Precautions for Repair ......Page 7-2 Adjustment and Replacement ....Page 7-2 Adjustment of Brake ......Page 7-2 Adjustment of Engine Clutch Section ..Page 7-2 Page 7-1... -

Page 78: Precautions For Repair

Important Make sure that the brake lever is locked Use Baroness genuine parts for replacement when gripping the lock lever while gripping and accessories. the brake lever. - Page 79 LM18GC・LM56GC / LM66TC Repair Adjustment of Engine Clutch Adjustment of Clutch Wire Adjust the clearance between the engine Important clutch and clutch facing so that it will be 0.5 - 1.0 mm (0.020 - 0.039 in) when the main Make sure that the wire is not cracked or clutch lever set to the "ON"...

- Page 80 LM18GC・LM56GC / LM66TC Repair Adjustment of Clutch Spring The factory default setting of the clutch spring total length is 63.0 mm (2.48 in). The longer the spring is set, the lighter clutch handling is provided. The shorter, the heavier. Make adjustment with the spring adjustment nut so that the total length of the clutch spring will be 63.0 mm (2.48...

-

Page 81: Appended Table

LM18GC・LM56GC / LM66TC Appended Table Tightening Torques ....... Page 8-2 Standard Tightening Torques ....Page 8-2 Principal Tightening Torques ....Page 8-4 Maintenance Schedule ......Page 8-5 List of Adjusted Values ......Page 8-7 Troubleshooting Procedures of Aftercut Appearance ......Page 8-8 Scalping .......... -

Page 82: Tightening Torques

LM18GC・LM56GC / LM66TC Appended Table Tightening Torques Important Refer to the Tightening Torque table. Note that the Baroness product warranty may not apply to defects caused by incorrect or overtorque tightening, etc. Standard Tightening Torques Bolts and Nuts Important A number of bolts are used in each part of this machine. - Page 83 LM18GC・LM56GC / LM66TC Appended Table General bolt Strength classification 4.8 Nominal diameter tib3yb-001 kgf-cm lb-in 3 - 5 30.59 - 50.99 26.55 - 44.26 7 - 9 71.38 - 91.77 61.96 - 79.66 14 - 19 142.76 - 193.74 123.91 - 168.17 29 - 38 295.71 - 387.49...

-

Page 84: Principal Tightening Torques

LM18GC・LM56GC / LM66TC Appended Table Principal Tightening Torques Tightening Torque by Model LM18GC/LM56GC/LM66GC/LM66TC Tighten the following bolts and nuts at the torque specified in the table. For thread locking adhesive, apply a middle strength thread locker (ThreeBond 1322 or equivalent anaerobic sealant). -

Page 85: Maintenance Schedule

LM18GC・LM56GC / LM66TC Appended Table Maintenance Schedule LM18GC/LM56GC/LM66GC/LM66TC Follow the maintenance schedule below. ●・・・Inspect, adjust, supply, clean (first time) ○・・・Inspect, adjust, supply, clean ▲・・・Replace (first time) △・・・Replace Maintenance Item Remarks Check bolts and nuts ○ ... - Page 86 LM18GC・LM56GC / LM66TC Appended Table Maintenance Item Remarks Check tire ○ Check damaged parts ○ ...

-

Page 87: List Of Adjusted Values

Grind/Replace blades Regrind blades (Reel cutter) ○ as and when required *1: Consult your local Baroness Dealer for this service. ・ *2: Refer to the Engine's Owner's Manual. ・ ・... -

Page 88: Troubleshooting Procedures Of Aftercut Appearance

LM18GC・LM56GC / LM66TC Appended Table Angled Mismatch Troubleshooting Procedures of Aftercut Appearance Is the cutting height on both sides adjusted to be the same? Scalping Adjustment of cutting height Is the roller bracket secured? Is the bed knife (bottom blade) chipped? -

Page 89: Overlap Marks

LM18GC・LM56GC / LM66TC Appended Table Overlap Marks Has the bed knife (bottom blade) become curved? Back lapping Surface grinding of bed knife (bottom blade) Replacement of bed knife (bottom blade) Loosening of blade engagement After loosening blade engagement, streaks still appear. -

Page 90: Blade Does Not Cut

LM18GC・LM56GC / LM66TC Appended Table Blade Does Not Cut Are genuine parts used for the blades? Is the grit size of the lapping Use lapping powder with a grit Replacement of blades with genuine parts powder #200 – #400? size of #200 – #400. -

Page 91: Uneven Blade Engagement

LM18GC・LM56GC / LM66TC Appended Table Uneven Blade Engagement The unevenness is a difference of tightening torque between the left and right cutter adjustment nuts, or blade engagement on only one side, which cannot be adjusted. Promptly resolve the issue in order to maintain the optimum performance of the machine. - Page 92 LM18GC・LM56GC / LM66TC Appended Table Page 8-12 Troubleshooting Procedures of Aftercut Appearance...

- Page 93 1-26, Miyuki-cho, Toyokawa-city, Tel : +81 - 533 - 84 - 1390 Head Office Aichi-pref, 442-8530 JAPAN Fax : +81 - 533 - 84 - 1220 LM56GC--UM--USZ/24A-00-S.K...