Summary of Contents for Toro 74603

- Page 1 Form No. 3357-831 Rev A TimeCutter® ZX440 Riding Mower Model No. 74603—Serial No. 270000001 and Up Register your product at www.Toro.com Original Instructions (EN)

-

Page 2: Introduction

finding a dealer, or to register your product. Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model Contact us at www.Toro.com. -

Page 3: Table Of Contents

Safety ..............4 Removing the Mower ......33 Safe Operating Practices ...... 4 Inspecting the Belts ......33 Toro Riding Mower Safety ....6 Replacing the Mower Belt ....33 Slope Chart ......... 7 Installing the Mower ......34 Safety and Instructional Decals .... 8 Replacing the Grass Deflector.... -

Page 4: Safety

Safety • Do not operate the mower without either the entire grass catcher or the guard in place. • Be alert, slow down and use caution when This machine meets or exceeds the B71.1-2003 making turns. Look behind and to the side specifications of the American National before changing directions. - Page 5 • Always keep the wheel motors engaged when • Never carry children, even with the blades off. going down slopes. Do not move the motion They may fall off and be seriously injured or control levers to the neutral position and coast interfere with safe machine operation.

-

Page 6: Toro Riding Mower Safety

• Check for proper brake operation frequently. Adjust and service as required. • Maintain or replace safety and instruction decals as necessary. • Use only genuine Toro replacement parts to ensure that original standards are maintained. -

Page 7: Slope Chart

Slope Chart... -

Page 8: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 114-1606 1. Entanglement hazard, belt—keep all guards in place. 93-7009 1. - Page 9 112-9840 1. Read the Operator’s 3. Remove the ignition key Manual. and read the instructions before servicing or 99-8936 performing maintenance. 2. Height of cut 1. Machine speed 4. Neutral 5. Reverse 2. Fast 3. Slow 104-8009 104-8032 1. Throttle 7.

- Page 10 Battery Symbols Some or all of these symbols are on your battery 1. Explosion hazard 6. Keep bystanders a safe 107-2474 distance from the battery. 2. No re, open ame, or 7. Wear eye protection; smoking. explosive gases can cause 1.

-

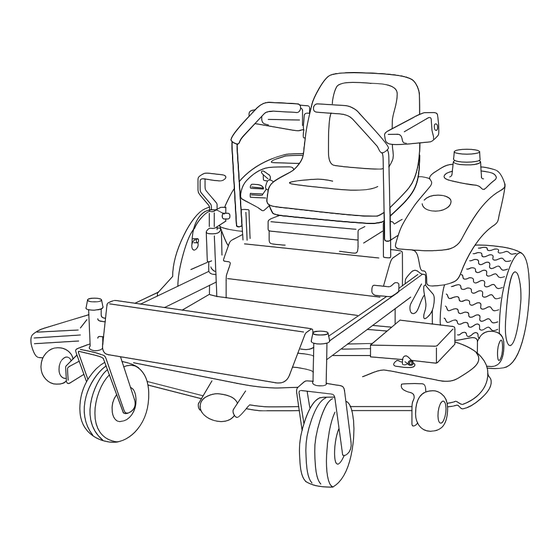

Page 11: Product Overview

Product Overview Figure 3 1. Seat 4. Height of cut lever 7. Anti-scalp wheel 10. Discharge chute 2. Control panel 5. Parking brake 8. Front castor wheel 11. Gas tank 9. Footrest 3. Motion control levers 6. Mower deck 12. Rear drive wheel Controls Become familiar with all of the controls (Figure 4 and Figure 5) before you start the engine and... -

Page 12: Operation

Operation Note: Determine the left and right sides of the machine from the normal operating position. Think Safety First Please carefully read all of the safety instructions and decals in the safety section. Knowing this information could help you, your family, pets or bystanders avoid injury. - Page 13 In certain conditions, gasoline is extremely In certain conditions during fueling, static flammable and highly explosive. A fire or electricity can be released causing a spark explosion from gasoline can burn you and which can ignite the gasoline vapors. A fire others and can damage property.

-

Page 14: Checking The Engine Oil Level

• Cleans the engine while it runs • Eliminates gum-like varnish buildup in the fuel system, which causes hard starting Important: Do not use fuel additives containing methanol or ethanol. Add the correct amount of gas stabilizer/conditioner to the gas. Note: A fuel stabilizer/conditioner is most Figure 7 effective when mixed with fresh gasoline. -

Page 15: Operating The Blades

Operating the Blades Important: Do not engage the starter for more than 10 seconds at a time. If the The blade control switch, represented by a power engine fails to start, allow a 60 second take-off (PTO) symbol, engages and disengages cool-down period between attempts. -

Page 16: Driving Forward Or Backward

Understanding the Safety Interlock the throttle control in the Fast position for best System performance. Always operate in the full throttle position. The safety interlock system is designed to prevent the engine from starting unless: • The parking brake is engaged. The machine can spin very rapidly. -

Page 17: Stopping The Machine

Backward 4. Secure the clevis pin with the hairpin cotter (Figure 13). 1. Move the levers to the center, unlocked position. 2. To go backward, slowly pull the motion control levers rearward (Figure 12). To go straight, apply equal pressure to both motion control levers (Figure 12). -

Page 18: Positioning The Seat

1. Remove the 2 screws and curved washers holding the control lever to the control arm G000911 shaft (Figure 16). 2. Move the control lever to the next set of holes. Secure the lever with the 2 screws and curved washers. -

Page 19: Side Discharge

Operating Tips Fast Throttle Setting For best mowing and maximum air circulation, operate the engine at Fast. Air is required to thoroughly cut grass clippings, so do not set the height-of-cut so low as to totally surround the mower by uncut grass. Always try to have one side of the mower free from uncut grass, which allows air to be drawn into the mower. -

Page 20: Blade Maintenance

File down any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade. Safe Towing Practices Tow only with a machine that has a hitch designed for towing. -

Page 21: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Check the safety system. • Check the engine oil level (more often in dirty or dusty conditions). Before each use or daily •... -

Page 22: Where To Add Grease

Where to Add Grease Lubricate the grease fittings as shown on the Check Service Reference Aid decal (Figure 18) located beneath the seat and the mower (Figure 19). Figure 20 Figure 18 Checking the Oil Level 1. Park the machine on a level surface, disengage the blade control switch, stop the engine, and remove the key. -

Page 23: Servicing The Air Cleaner

Important: Do not overfill the crankcase Changing the Oil Filter with oil because the engine may be Replace the oil filter every 200 hours or every damaged. other oil change. Changing and Draining the Oil Note: Change the oil filter more frequently when operating conditions are extremely dusty or sandy. - Page 24 3. Clean around the air cleaner to prevent dirt from getting into the engine and causing damage. Unscrew the knob and remove the air cleaner cover (Figure 24). Figure 25 1. Foam element 2. Oil 2. Paper Element A. Lightly tap the element on a flat surface to remove dust and dirt (Figure 26).

-

Page 25: Spark Plug

Spark Plug Important: Never clean the spark plug(s). Always replace the spark plug(s) Check the spark plug(s) after every 200 operating when it has a black coating, worn hours. Make sure that the air gap between the electrodes, an oily film, or cracks. center and side electrodes is correct before 2. -

Page 26: Replacing The Fuel Filter

1. Park the machine on a level surface, to ensure 2. Stop the engine, remove the key, and wait for that the fuel tank drains completely. all moving parts to stop before leaving the operating position. 2. Disengage the blade control switch and move the control levers to the neutral locked position 3. -

Page 27: Removing The Battery

Removing the Battery Battery terminals or metal tools could short against metal tractor components causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury. • When removing or installing the battery, do not allow the battery terminals to touch any metal parts of the tractor. -

Page 28: Servicing The Fuses

Charging the Battery 2. Look at the side of the battery. The electrolyte must be up to the Upper line (Figure 31). Important: Always keep the battery Do not allow the electrolyte to fall below the fully charged (1.260 specific gravity). This Lower line (Figure 31). -

Page 29: Drive System Maintenance

File down any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a Drive System genuine Toro replacement blade. For convenient sharpening and replacement, you may want to Maintenance keep extra blades on hand. -

Page 30: Removing The Blades

3. Rotate the blades until the ends face forward genuine Toro replacement blades. Replacement and backward (Figure 36). Measure from a blades made by other manufacturers may result in level surface to the cutting edge of the blades non-conformance with safety standards. -

Page 31: Leveling The Mower From

original angle. The blade retains its balance if 2. Check the air pressure of all four tires. If the same amount of material is removed from needed, adjust to the recommended inflation; both cutting edges. refer to Tire Press. 3. Set the height-of-cut at 3 inch (76 mm). 4. -

Page 32: Adjusting The Front-To-Rear Blade Slope

Adjusting the Front-to-Rear the flat surface. If the front blade tip is not Blade Slope 1/16-5/16 inch (1.6-7.9 mm) lower than the rear blade tip, adjust the front trunion rods. Check the front-to-rear blade level any time you install the mower. If the front of the mower is more than 5/16 inch (7.9 mm) lower than the rear of the mower, adjust the blade level using the following instructions:... -

Page 33: Removing The Mower

13. When the front-to-rear blade slope is correct, tighten the jam nuts (Figure 43 and Figure 45). 14. Recheck the side-to-side level of the mower; refer to Leveling the Mower from Side-to-Side. 15. Check the height of the anti-scalp rollers; refer to Adjusting the Anti-Scalp Rollers. -

Page 34: Installing The Mower

The spring is under tension when installed and can cause personal injury. Do not remove the spring from the spring eye bolt. 5. Route the new belt through the idler arm and around the idler pulley (Figure 48). Figure 49 Top View 1. -

Page 35: Replacing The Grass Deflector

Replacing the Grass Note: It may be helpful to press down near Deector the end of the bolt with a 9/16 inch open end wrench to align the bolt with the second hole on the mower bracket and grass deflector. 5. - Page 36 Figure 51 3. Hose 1. Washout tting 2. Coupling 5. Lower the mower to the lowest height-of-cut. 6. Sit on the seat and start the engine. Engage the blade control switch and let the mower run for one to three minutes. 7.

-

Page 37: Storage

Storage C. Restart the engine and run it until it stops. D. Choke or prime the engine. Start and run Cleaning and Storage the engine until it will not start. Operate the primer, if equipped, several times to ensure 1. Disengage the blade control switch, set the no fuel remains in the primer system. -

Page 38: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The engine overheats. 1. The engine load is 1. Reduce ground speed. excessive. 2. The oil level in the 2. Add oil to the crankcase. crankcase is low. 3. The cooling ns and 3. Remove the obstruction air passages under the from the cooling ns and engine blower housing... - Page 39 Problem Possible Cause Corrective Action The engine will not start, 1. The fuel tank is empty. 1. Fill the fuel tank. starts hard, or fails to keep 2. The fuel valve turned off. 2. Open the fuel valve. running. 3. The choke is not on. 3.

- Page 40 Problem Possible Cause Corrective Action There is abnormal vibration. 1. The engine mounting 1. Tighten the engine bolts are loose. mounting bolts. 2. The engine pulley, idler 2. Tighten the appropriate pulley, or blade pulley is pulley. loose. 3. The engine pulley is 3.

-

Page 41: Schematics

Schematics Electrical Schematic (Rev. A) - Page 43 The use of any add-on or modied parts will be grounds for disallowing a warranty claim made in accordance with this article. The Toro® Company will not be liable under this Article to warrant failures of warranted parts caused by the use of an add-on or modied part.

-

Page 44: The Toro Total Coverage Guarantee

(Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.