Siemens SIMOTICS FD 1LH1 Manuals

Manuals and User Guides for Siemens SIMOTICS FD 1LH1. We have 2 Siemens SIMOTICS FD 1LH1 manuals available for free PDF download: Operating Instructions & Installation Instructions

Siemens SIMOTICS FD 1LH1 Operating Instructions & Installation Instructions (174 pages)

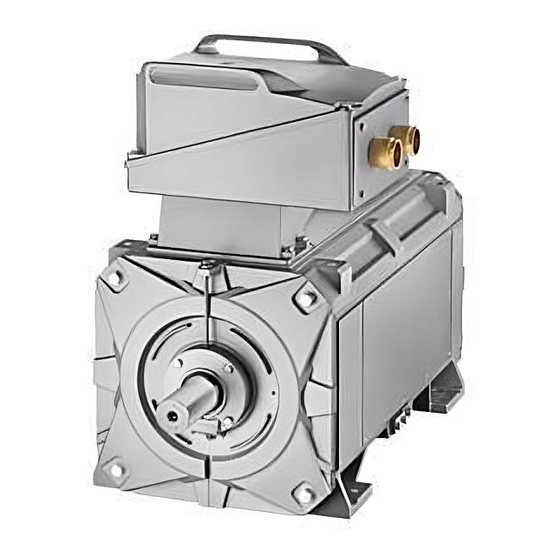

Induction motor

Table of Contents

-

Introduction13

-

Description21

-

Image22

-

Storage40

-

Image46

-

Assembly49

-

Image68

-

Terminal Box71

-

Image72

-

Image73

-

Image75

-

Image76

-

Preparation80

-

Connection83

-

Start-Up97

-

Test Run101

-

Switching off103

-

Image105

-

Image106

-

Operation111

-

Stoppages113

-

Faults117

-

Maintenance123

-

Remove V Ring135

-

Image136

-

Image138

-

Seal the Motor140

-

Image140

-

Spare Parts141

-

Ordering Data141

-

Roller Bearings141

-

Image142

-

Image144

-

Image145

-

Image149

-

Image154

-

Image155

-

Image156

-

Image157

-

Disposal159

-

Index169

Advertisement

Siemens SIMOTICS FD 1LH1 Operating Instructions & Installation Instructions (174 pages)

Low-voltage motor

Table of Contents

-

Introduction13

-

Description21

-

Power Loss32

-

Transport40

-

Storage44

-

Assembly53

-

Basic Rules73

-

Terminal Box74

-

Preparation83

-

Start-Up97

-

Test Run102

-

Switching off104

-

Operation111

-

Stoppages113

-

Faults117

-

Maintenance123

-

Remove V Ring134

-

Seal the Motor139

-

Spare Parts141

-

Ordering Data141

-

Disposal159

-

Index169

Advertisement