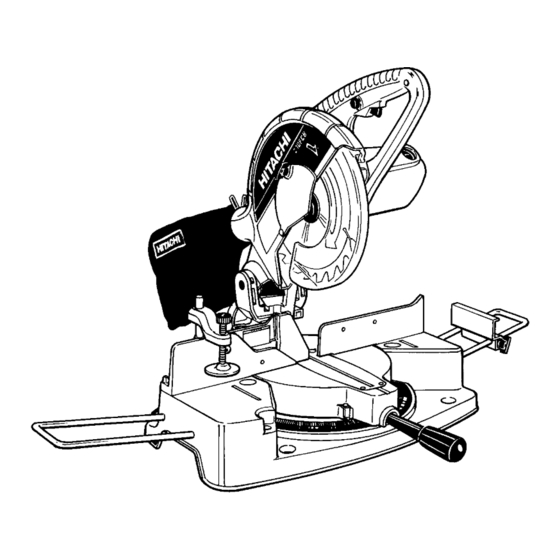

Hitachi C-10FCB Technical Data And Service Manualice Manual

Compound saw

Hide thumbs

Also See for C-10FCB:

- Instruction manual (64 pages) ,

- Handling instructions manual (43 pages) ,

- Handling instructions manual (8 pages)

Summary of Contents for Hitachi C-10FCB

- Page 1 MODEL C 10FCB POWER TOOLS TECHNICAL DATA COMPOUND SAW SERVICE MANUAL C 10FCB LIST No. E931 Apr. 2001 SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT...

-

Page 2: Table Of Contents

CONTENTS Page 1. PRODUCT NAME ......................... 1 2. MARKETING OBJECTIVE ......................1 3. APPLICATIONS ........................... 1 4. SELLING POINTS ........................1 4-1. Selling Point Descriptions ......................2 5. SPECIFICATIONS ........................4 6. COMPARISONS WITH SIMILAR PRODUCTS ................5 7. PRECAUTIONS IN SALES PROMOTION ................... 6 7-1. -

Page 3: Product Name

The Model C 10FCB has been newly developed as a successor of the current Models C 10FC, C 10FC2 and C 10FCA (REXON's OEM products) intended to be manufactured in the factory of Hitachi Koki Group (HKF) to keep high quality and to adopt Hitachi Koki's original design. Vigorous sales promotion and market share increases are anticipated with the introduction of the new Model C 10FCB. -

Page 4: Selling Point Descriptions

4-1. Selling Point Descriptions (1) Press cutting Table 1 (Unit: mm) Width (W) Workpiece Maker HITACHI Model Height (H) C 10FCB Max. cutting dimension Height x Width 59 x 144 (2-5/16" x 5-21/32") (H x W) 89 x 101 (3-1/2" x 3-31/32") Fig. - Page 5 (4) Compound cutting through use of miter and bevel cutting functions Table 4 (Unit: mm) Maker Width (W) HITACHI Model C 10FCB Max. cutting dimension Height (H) Left bevel 45˚ Right/Left miter 45˚ 41 x 102 (1-5/8" x 4") Height x Width (H x W) * When the saw blade section (head) is inclined 45˚...

-

Page 6: Specifications

5. SPECIFICATIONS 59 mm (2-5/16") x 144 mm (5-21/32") 0˚ (Right angle) Maximum 89 mm (3-1/2") x 101 mm (3-31/32") cutting Miter right/left 45˚ 59 mm (2-5/16") x 102 mm (4") [Right 60˚: 59 mm (2-5/16") x 72 mm (2-13/16")] dimentions Bevel left 45˚... -

Page 7: Comparisons With Similar Products

6. COMPARISONS WITH SIMILAR PRODUCTS Maker/Model HITACHI HITACHI C 10FC2/C 10FC C 10FCB Item 67 mm x 146 mm (2-5/8" x 5-3/4") 59 mm x 144 mm (2-5/16" x 5-21/32") 89 mm x 92 mm 70 mm x 146 mm 69 mm x 130 mm 0˚... -

Page 8: Precautions In Sales Promotion

7. PRECAUTIONS IN SALES PROMOTION In the interest of promoting the safest and most efficient use of the Model C 10FCB Compound Saw by all of our customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer seriously recognizes the importance of the contents of the Instruction Manual, and fully understands the meaning of the precautions listed on the various Caution Plates attached to each machine. -

Page 9: Adjustment And Operational Precautions

(4) Caution plate (C) For the U.S.A. and Canada only The caution plate (C) specified by the UL is affixed on the upper right-hand portion of the gear case. Please instruct users to strictly observe the contents 1 to 9 in the caution plate (C) shown above. 8. -

Page 10: How To Use The Vise Assembly

8-3. How to Use The Vise Assembly (1) The vise assembly can be mounted on either the left fence Screw holder Knob 6 mm wing (fence (B)) or the right fence (fence (A)) by loosening bolt (B) 6 mm wing bolt (A). (2) The screw holder can be raised or lowered according to the Vise plate height of the workpiece by loosening 6 mm wing bolt (B). -

Page 11: Cutting Operation

8-5. Cutting Operation (1) Cutting efficiency will be reduced if a dull saw blade is used, if an excessively long extension cord is used, or if the wire gauge of the extension cord is too small. (For details on extension cords, please refer to the Instruction Manual.) This is particularly important when cutting materials with dimensions which are at or near the maximum capacity for the machine. - Page 12 (6) Compound (miter + bevel) cutting Compound cutting can be accomplished by combining the miter cutting and bevel cutting operations described in paragraphs (4) and (5) above. (For details, please refer to the Instruction Manual.) When the saw blade section (head) is inclined 45˚ to the left, the table can be turned up to 45˚ to the right and left. (7) Cut surface quality during miter/bevel cutting The quality of the cut surface depends on the type [Miter cutting]...

-

Page 13: Adjustment Of Components

9. ADJUSTMENT OF COMPONENTS 9-1. Bevel Angle Adjustment Before the power tool is shipped from the factory, it is adjusted for 0˚ and left 45˚ bevel cutting angles. The positioning and bevel cutting angle can be adjusted by changing the height of the 8 mm bolt (maximum bevel cutting angle is 45˚). -

Page 14: Precautions In Disassembly And Reassembly

11. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY Please follow the precautions below for disassembly and reassembly procedures. The circled numbers in the following figures and the [Bold] numbers in the descriptions below correspond to the item numbers in the Parts List and exploded assembly diagrams. CAUTION: Prior to attempting disassembly or replacement of the saw blade, ensure that the power cord plug is disconnected from the power source. - Page 15 1. Remove the four Bolts (W/Washers) M8 x 35 (Black) and remove Fence (A) [46] and Fence (B) [31]. 2. Loosen the Clamp Lever [2] and remove the Machine Screw (W/Washers) M6 x 12 (Black) [1]. Turn the Bolt (Left Hand) M10 x 40 [3] and remove it from the Hinge [7]. 3.

- Page 16 B. Safety cover and link Spindle and spring Tools required: • Phillips screwdriver • Hex. bar wrench 4 mm • Hex. bar wrench 3 mm • Box wrench 10 mm (standard accessory) Fig. 16 --- 14 ---...

- Page 17 1. Remove the Bolt (Left Hand) M7 x 17.5 [122] with the box wrench 10 mm (standard accessory). Then Washers (B) and (C) [120], TCT Saw Blade 255 mm [118] and Washers (A) and (D) can be removed in this order. 2.

- Page 18 C. Armature ass'y Cord, stator ass'y and housing ass'y Tools required: • Phillips screwdriver • Flat-blade screwdriver • Plastic hammer Fig. 17 1. Remove the Brush Cap [64] and the Carbon Brush [63]. 2. Remove the four Machine Screws (W/Washers) M5 x 45 (Black). Then the Housing Ass'y can be removed together with the Handle Cover [70] from the Gear Case [85].

-

Page 19: Reassembly

5 MΩ. (2) When replacing the Spring [5], apply 5 grams of Hitachi Motor Grease No. 29 (Code No. 930035) to the inner circumference of the new Spring [5] prior to reassembly. -

Page 20: Wiring Diagram

11-3. Wiring Diagram Carefully ensure that wiring is accomplished as illustrated below. As incorrect wiring will result in lack of rotation, reverse rotation or other malfunctions, close attention is absolutely necessary. Wiring diagram (for the U.S.A. and Canada only) Switch Black Blue White... -

Page 21: Lead Wire Precautions

Wiring diagram (except the U.S.A. and Canada) Black or red Red or black Periphery of stator core Armature ass'y Red or black Stator coil Black or red Stator ass'y Fig. 21 Actual wiring diagram (except the U.S.A. and Canada) Noise suppressor (It may not be provided depending on the destinations.) Black or red Red or black... -

Page 22: No-Load Current

Base [49], tighten the Nylon Nut M8 [32] so that the Turn Table [38] turns smoothly without excessive play or vibration. During reassembly, liberally apply grease (Hitachi Motor Grease No. 29, Code No. 930035 is recommended) at the point marked "A" in Fig. 24. -

Page 23: Lubrication

11-7. Lubrication Advise the customer to lubricate the machine as indicated below at least once a month. Also, prior to applying lubrication, any sawdust, dirt or other foreign matter should be thoroughly wiped away with a soft cloth. (1) Swiveling section of the Gear Case [85] and the Hinge [7] Coat the swiveling and sliding portion of the Gear Case [85] and the Hinge [7] with machine oil. -

Page 24: Tightening Torque

11-9. Tightening Torque • Machine Screw (W/Washers) M6 x 12 (Black) [1] ........34.7 in-lbs. (3.9 N•m, 40 kgf•m) • Hex. Socket Set Screw M6 x 10 [10] [90] ..........34.7 in-lbs. (3.9 N•m, 40 kgf•m) • Machine Screw (W/Washers) M4 x 8 (Black) [12] [36] [43] ....10.4 in-lbs. (1.2 N•m, 12 kgf•m) •... -

Page 25: Repair Guide

12. REPAIR GUIDE Unit: mm Factory Inspection, repair or Item Phenomenon Cause standard adjustment • Adjust squareness with the a Inaccurate 0.15/100 Inaccurate cutting Nylock Bolt M8 x 25 [35]. squareness between (Dummy disc) Inaccurate • • • the turn table and the (Fig. - Page 26 Factory Inspection, repair or Item Phenomenon Cause standard adjustment 0.1/height of • Replace Fence (A) [46] or f Inaccurate squareness (Continued) between the fence fence Fence (B) [31]. (Fig. 28) and the turn table and/ or the base causes the workpiece to tilt at Fence an angle and prevent accurate cutting.

- Page 27 Factory Inspection, repair or Item Phenomenon Cause standard adjustment Rough cut surface a Large deflection of the 0.2/245 • Same as the Item 1- b . saw blade (It causes (Dummy disc) Parallelism (A) = 0.02/51 rough cut surface.) Parallelism (B) = 0.02/51 b Each surface Washer (A) 0.02/51...

- Page 28 • Resharpen the saw blade. is applied due to dull saw blade. d Incorrect saw blade is ------ • Use a suitable Hitachi-supplied used. saw blade. • If the saw blade has a large number of teeth, the cutting resistance will be increased.

-

Page 29: Standard Repair Time (Unit) Schedules

13. STANDARD REPAIR TIME (UNIT) SCHEDULES Variable 70 min. MODEL Fixed Work Flow C 10FCB General Assembly Carbon Brush Armature Ass'y Fixed Cost Gear Case Link Stator Ass'y Lock Spring Handle Cover Link Safety Cover 0 min. Housing Ass'y Lock Lever Cord Safety Cover Table Insert... - Page 30 LIST NO. E931 ELECTRIC TOOL PARTS LIST COMPOUND SAW 2001 • • Model C 10FCB (E2)

- Page 31 C 10FCB --- 2 --- 4 -- 01...

- Page 32 PARTS C 10FCB ITEM CODE NO. DESCRIPTION REMARKS USED 307-232 MACHINE SCREW (W/WASHERS) M6X12 (BLACK) 312-488 CLAMP LEVER 318-933 BOLT (LEFT HAND) M10X40 318-934 SPECIAL WASHER 318-939 SPRING 318-938 SLEEVE 318-951 HINGE 318-935 SHAFT (C) 984-528 O-RING (P-6) 968-247 HEX. SOCKET SET SCREW M6X10 302-518 STOPPER PIN ASS’Y INCLUD.9...

- Page 33 PARTS C 10FCB ITEM CODE NO. DESCRIPTION REMARKS USED 301-806 WING BOLT M6X15 CAUTION PLATE (B) 318-928 SHAFT (B) 500-214Z CORD (CORD ARMOR D10.7) 315-897 CORD (CORD ARMOR D10.7) FOR CHN 952-802Z CORD (CORD ARMOR D10.7) FOR SIN,MLA (CORD ARMOR D10.7) FOR AUS,NZL 500-453Z CORD (CORD ARMOR D10.7) FOR USA,CAN...

- Page 34 600-3VV BALL BEARING 6003VVCMPS2L 320-107 RETURN SPRING (B) 318-943 SAFETY COVER 307-731 COVER 949-322 FLAT HD. SCREW M4X10 (10 PCS.) HITACHI LABEL 308-789 WASHER (D) 318-961 WASHER (A) FOR CHN,FRG,AUT,GBR,FRA,HOL,BEL,ESP, SUI,ITA,NOR,SWE,DEN,FIN 318-963 TCT SAW BLADE 255MM-D15.88 HOLE-NT24 318-964 TCT SAW BLADE 255MM-D25.4 HOLE-NT100 319-106 TCT SAW BLADE 255MM-D25.4 HOLE-NT24...

-

Page 35: Standard Accessories

C 10FCB PARTS ITEM CODE NO. DESCRIPTION REMARKS USED 976-819 COLLAR (B) FOR D25.4 HOLE 974-663Z COLLAR (A) FOR D30 HOLE FOR AUS,NZL,AUT,GBR,FRA,HOL,BEL,ESP, SUI,ITA,NOR,SWE,DEN,FIN 998-838 WASHER (C) 318-962 WASHER (B) FOR CHN,FRG,AUT,GBR,FRA,HOL,BEL,ESP, SUI,ITA,NOR,SWE,DEN,FIN 940-845 WASHER 996-258 BOLT (LEFT HAND) M7X17.5 949-567 LOCK NUT M6 (10 PCS.) 949-454...