Summary of Contents for Hitachi C 6SE

-

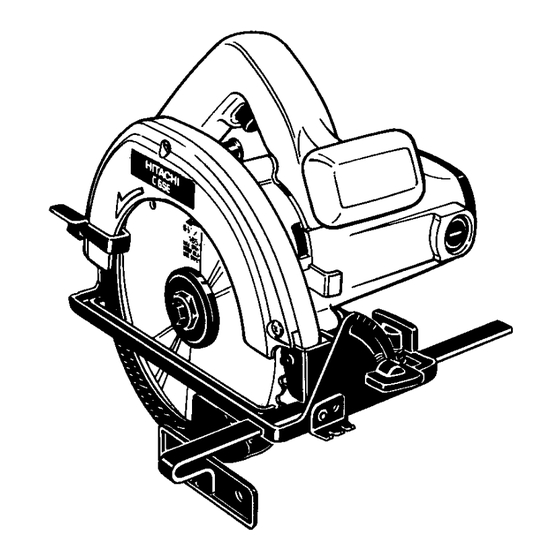

Page 1: Circular Saws

MODELS C 6SE C 7SE POWER TOOLS TECHNICAL DATA CIRCULAR SAWS C 6SE, C 7SE SERVICE MANUAL C 6SE C 7SE LIST Nos. C 6SE: 0587 Sep. 1999 C 7SE: 0588 SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT... - Page 2 REMARK: Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s) is(are) used in the place of company name(s) and model name(s) of our competitor(s). The symbol(s) utilized here is(are) as follows: C 6SE Competitor Symbol Utilized Model Name Company Name...

-

Page 3: Table Of Contents

[ Appendix ] Assembly Diagram for C 6SE • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •... -

Page 4: Product Name

Hitachi Circular Saw, Model C 7SE [190 mm (7-1/2")] 2. MARKETING OBJECTIVE The Models C 6SE and C 7SE have been developed based on the current Models C6 and C7. The key features of the Models C 6SE and C 7SE are as follows: (1) Double-insulated construction. -

Page 5: Selling Point Descriptions

High performance TCT saw blade (40 teeth) is provided as standard instead of the conventional combination blade. The Models C 6SE and C 7SE provide greater maximum cutting depth than the conventional models by using a 165 mm dia. TCT saw blade and a 190 mm dia. TCT saw blade respectively. -

Page 6: Specifications

5. SPECIFICATIONS Model C 6SE C 7SE Saw blade diameter 165 mm (6-1/2") 190 mm (7-1/2") at 90˚ 0 --- 56 mm (0 --- 2-7/32") 0 --- 67 mm (0 --- 2-5/8") Cutting depth at 45˚ Max. 37 mm (1-15/32") Max. -

Page 7: Comparisons With Similar Products

7. PRECAUTIONS IN SALES PROMOTION In the interest of promoting the safest and most efficient use of the Models C 6SE and C 7SE Circular Saws by all of our customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer seriously recognizes the importance of the contents of the Handling Instructions. -

Page 8: Precautions In Disassembly And Reassembly

Model C 6SE, and the < > numbers for the Model C 7SE. During disassembly and reassembly, and at all times as well, sufficient care must be exercised in handling to ensure that there is no deviation in the flatness of the bottom surface of the base and in its perpendicularity with relation to the saw blade. -

Page 9: Reassembly

8-2. Reassembly Reassembly can be accomplished by following the disassembly procedures in reverse. However, particular attention should be given to the following items. (1) Tightening torquer for fastening screws and bolts • M3 Machine Screws 0.2 N m (8 2 kgf •... - Page 10 (4) Reassemble the Stator Ass'y [28] <27> As shown in Fig. 4, insert a guide bar [J-132 stator press pins (Special repair tool, Code No. 970911) are recommended] into the Stator Ass'y [28] <27> and the Housing Ass’y [25] <24> to accurately align the screw hole on the Stator Ass'y [28] <27>...

- Page 11 (5) Wiring Wiring should be performed as shown below. Be careful not to sandwich the internal wires between the Handle Cover [57] <56> and the Housing Ass'y [25] <24>. 1. Wiring diagram [A] For Australia and New Zealand Black or blue Noise Switch suppressor...

- Page 12 2. Schematic diagram [A] For Australia [B] For New Zealand Black Blue Blue Blue Brown Brown [C] For Korea [D] For other countries [ASEAN, M.E. Asia, Taiwan] White, blue Blue or black Brown Black or brown White or blue Blue --- 9 ---...

-

Page 13: Insulation Tests

Allowable deflection level of the saw blade shall be as follows. Model Measuring point Allowable level C 6SE, C 7SE 0.5 mm max. 8-5. Cleaning the Case When the unit becomes soiled, clean it with a clean soft rag moistened with soapy water. Since chloric solvents, gasoline and thinner tend to melt plastic material, their use for cleaning is absolutely avoided. -

Page 14: Standard Repair Time (Unit) Schedules

9. STANDARD REPAIR TIME (UNIT) SCHEDULES Variable MODEL 60 min. Fixed Work Flow C 6SE C 7SE Switch Cord Housing Ass’y Stator Ass’y General Assembly Saw Blade Armature Safety Cover Ball Bearing (608VV) Return Spring Ball Bearing (6000VV) Gear Cover Ass’y... -

Page 15: Assembly Diagram For C 6Se

Assembly Diagram for C 6SE --- 12 ---... - Page 16 C 6SE PARTS ITEM CODE NO. DESCRIPTION REMARKS USED 606-ZZM BALL BEARING 606ZZC2PS2L 317-932 SPINDLE AND GEAR SET 873-095 O-RING (P-16) 941-048 BEARING HOLDER 990-430 SEAL LOCK FLAT HD. SCREW M4X10 317-930 SAFETY COVER 957-062 RETURN SPRING 620-2VV BALL BEARING 6202VVCMPS2L...

- Page 17 C 6SE PARTS ITEM CODE NO. DESCRIPTION REMARKS USED 999-043 CARBON BRUSH (1 PAIR) 935-829 BRUSH CAP 980-063 TERMINAL FOR CORD 981-373 TUBE (D) FOR CORD 953-327 CORD ARMOR D8.8 938-051 CORD ARMOR D10.1 937-631 CORD CLIP 984-750 TAPPING SCREW (W/FLANGE) D4X16 953-174 HEX.

-

Page 18: Standard Accessories

C 6SE STANDARD ACCESSORIES ITEM CODE NO. DESCRIPTION REMARKS USED 940-543 BOX WRENCH 10MM 316-106 GUIDE WITH WING BOLT AND SPRING OPTIONAL ACCESSORIES ITEM CODE NO. DESCRIPTION REMARKS USED 949-172 SAW BLADE (COMBINATION) 160MM-D19 HOLE 879-096 PLANER SAW BLADE 160MM-D19 HOLE... -

Page 19: Assembly Diagram For C 7Se

Assembly Diagram for C 7SE --- 16 ---... - Page 20 TCT SAW BLADE 190MM-D25.4 HOLE-NT40 FOR TPE 957-064 WASHER (B) 957-749 BOLT (W/WASHER) M7X17.5 317-926 SAW COVER HITACHI LABEL 949-219 MACHINE SCREW M4X16 (10 PCS.) 301-653 TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 961-732 TAIL COVER 302-434 MACHINE SCREW (W/WASHERS) M5X45 (BLACK)

- Page 21 C 7SE PARTS ITEM CODE NO. DESCRIPTION REMARKS USED 935-829 BRUSH CAP 980-063 TERMINAL FOR CORD 981-373 TUBE (D) FOR CORD 953-327 CORD ARMOR D8.8 938-051 CORD ARMOR D10.1 937-631 CORD CLIP 984-750 TAPPING SCREW (W/FLANGE) D4X16 961-501 HEX. HD. TAPPING SCREW D5X60 961-729 CUSHION 949-794...

- Page 22 C 7SE STANDARD ACCESSORIES ITEM CODE NO. DESCRIPTION REMARKS USED 940-543 BOX WRENCH 10MM 316-106 GUIDE WITH WING BOLT AND SPRING OPTIONAL ACCESSORIES ITEM CODE NO. DESCRIPTION REMARKS USED 940-878 SAW BLADE (COMBINATION) 185MM-D19 HOLE 879-099 SAW BLADE (RIP) 185MM-D19 HOLE-NT36 879-101 PLANER SAW BLADE 185MM-D19 HOLE 879-100...